Unlocking Hydrocolloid Synergy: A Complete Guide + Free Compatibility Matrix Download

SUBSCRIBE TO OUR BLOG

Promotions, new products, and recipes.

Hydrocolloids are the unsung heroes of food science. From creating creamy sauces to stabilizing plant-based dairy alternatives, they shape the texture, mouthfeel, and stability of countless foods we eat every day. But here’s the challenge: hydrocolloids don’t always play nicely together. Some combinations form powerful synergies, while others lead to separation, graininess, or total recipe failure.

That’s why we created the Hydrocolloid Compatibility Matrix, a free downloadable guide that helps chefs, food technologists, and home experimenters quickly understand which hydrocolloids complement each other and which should be avoided.

👉 📥 Download the Hydrocolloid Compatibility Matrix (PDF)

Why Hydrocolloid Compatibility Matters

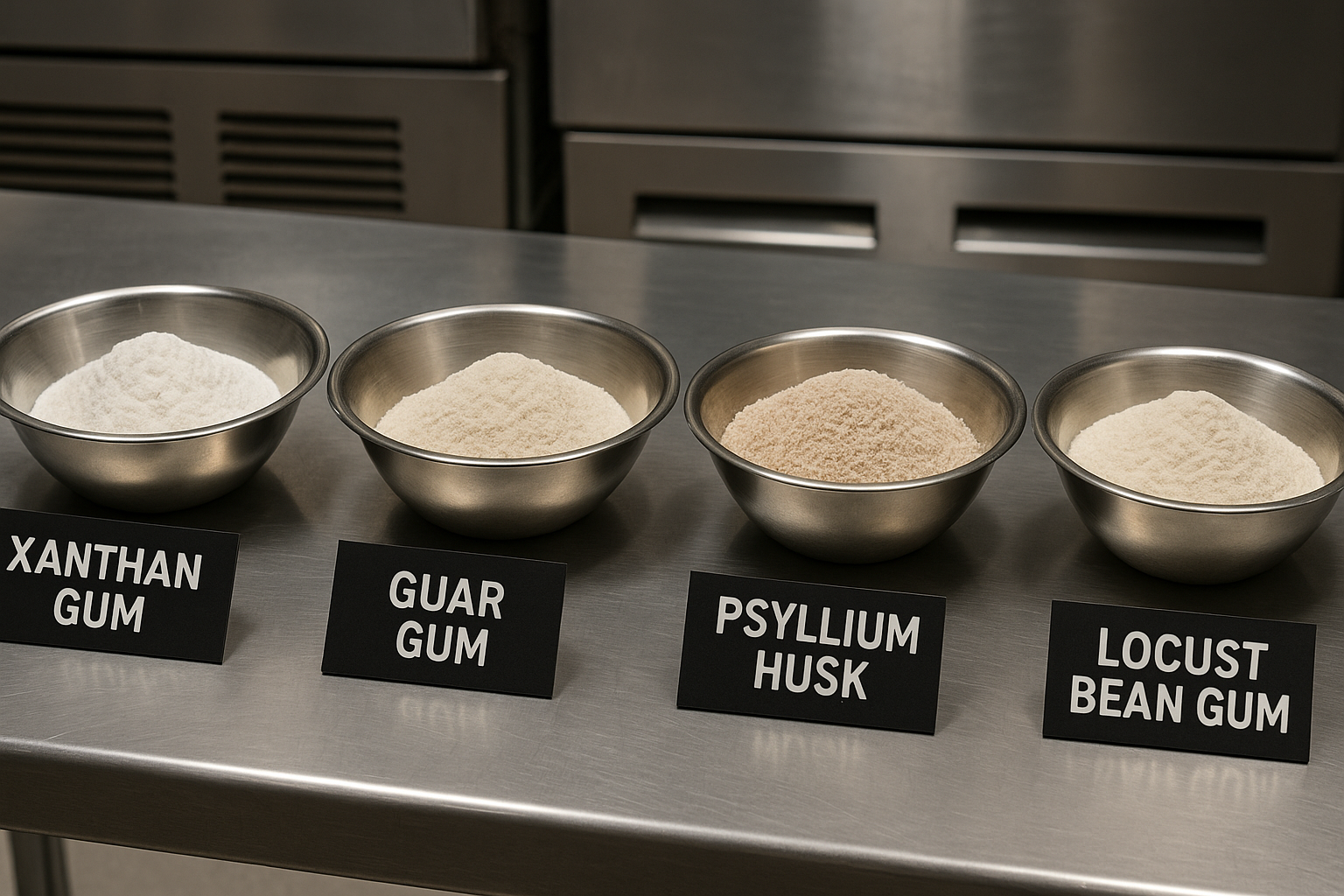

Hydrocolloids like xanthan gum, guar gum, carrageenan, and alginate are often used in small amounts, but their impact is huge. Choosing the right pairing can mean:

-

A sauce that stays smooth instead of separating.

-

A plant-based cheese that slices perfectly instead of crumbling.

-

An ice cream that remains creamy without ice crystal growth.

When the wrong hydrocolloids are paired, the results can be unpredictable. But when chosen wisely, hydrocolloid synergies reduce ingredient costs, improve stability, and create textures that are otherwise impossible.

Key Hydrocolloid Pairings Explained

Here are some of the most important and commonly used hydrocolloid combinations:

1. Xanthan Gum + Guar Gum

One of the most famous hydrocolloid pairings, xanthan and guar gum are often used together in gluten-free baking and beverage stabilization.

-

Xanthan gum provides viscosity and suspension power.

-

Guar gum adds smooth body and elasticity.

-

Together: They form a synergy where the viscosity is greater than the sum of the parts. This means you can use less of each gum for stronger thickening power.

This duo is especially valuable in gluten-free bread, giving dough elasticity and chewiness without gluten.

2. Carrageenan + Locust Bean Gum (LBG)

This is another classic hydrocolloid pairing, especially in dairy and dairy-alternative products.

-

Carrageenan provides gel strength and stability.

-

Locust bean gum works to improve elasticity and reduce brittleness.

-

Together: They form strong, elastic gels with creamy textures.

This combination is widely used in ice cream, puddings, and processed cheeses, where stability and creaminess are essential.

3. Alginate + Calcium

While not a hydrocolloid-hydrocolloid pairing, calcium plays a critical role in unlocking alginate’s potential.

-

Alginate forms gels in the presence of calcium ions.

-

This makes it perfect for spherification, encapsulation, and slow-release food applications.

-

Pairing alginate with calcium chloride or calcium lactate allows chefs to create iconic “molecular gastronomy” effects like fruit caviar or olive spheres.

4. Pectin + Calcium

Pectin comes in two main types: high methoxyl (HM) and low methoxyl (LM).

-

HM pectin requires sugar and acid to gel, making it perfect for jams and jellies.

-

LM pectin reacts with calcium, allowing it to gel even in low-sugar environments.

-

This makes LM pectin the go-to hydrocolloid for low-sugar or diabetic-friendly jams, fruit gels, and yogurt stabilizers.

5. Xanthan Gum + Konjac Gum

This duo creates elastic gels with unique textures.

-

Used in vegan meat alternatives, the combination mimics the bite and chew of real meat.

-

It also appears in plant-based seafood formulations, where it provides both structure and juiciness.

6. Agar + Locust Bean Gum

Agar gels can be brittle on their own. Locust bean gum helps modify that brittleness.

-

Agar provides firm gels that set at room temperature.

-

Locust bean gum softens the texture, making it less rigid.

-

Together, they create smoother, more elastic gels used in desserts, confectionery, and even microbiology media.

How to Read the Compatibility Matrix

The Hydrocolloid Compatibility Matrix is designed to make these relationships clear at a glance:

-

Green dots ✅: Strong synergy—these hydrocolloids work well together.

-

Yellow dots ⚠️: Caution—may work in some applications, but test carefully.

-

Red dots ❌: Incompatible—likely to cause separation or instability.

By keeping this chart handy, you’ll know whether your formulation idea is feasible before spending time and ingredients testing.

Applications in Food Science & Industry

The value of hydrocolloid compatibility isn’t just academic—it drives innovation across industries:

-

Gluten-Free Baking: Xanthan + guar gives structure to dough without wheat.

-

Plant-Based Dairy: Carrageenan + LBG create creamy textures in vegan cheese and yogurt.

-

Frozen Desserts: Locust bean gum + guar gum control ice crystal growth in ice cream.

-

Sauces & Dressings: Xanthan stabilizes emulsions, sometimes combined with gum arabic for smoothness.

-

Molecular Gastronomy: Alginate + calcium bring culinary creativity to life.

Free Download: Hydrocolloid Compatibility Matrix

We’ve distilled years of research and food science expertise into a single, easy-to-read chart that you can reference in your kitchen or lab.

👉 📥 Download the Hydrocolloid Compatibility Matrix (PDF)

Use it as your formulation cheat sheet for choosing the right gum, pectin, or alginate combinations.

FAQs About Hydrocolloid Compatibility

1. Why do some hydrocolloids work better together than others?

Hydrocolloids interact at a molecular level—some form cooperative structures (like xanthan + guar), while others repel or destabilize each other.

2. Can I use the chart for any recipe?

Yes, but it’s a starting point. Formulation success also depends on concentration, pH, temperature, and other ingredients.

3. What’s the best combination for gluten-free bread?

Xanthan gum + guar gum is widely used to mimic gluten’s elasticity.

4. Are all hydrocolloid interactions reversible?

No. Some, like alginate + calcium, form irreversible gels, while others can be remelted or reshaped.

5. Which hydrocolloid pairs are best for plant-based cheeses?

Carrageenan + LBG, or xanthan + konjac, depending on desired firmness and elasticity.

6. Where can I buy high-quality hydrocolloids?

You can order premium, food-grade hydrocolloids directly from Cape Crystal Brands.

|

About the Author Ed is the founder of Cape Crystal Brands, editor of the Beginner’s Guide to Hydrocolloids, and a passionate advocate for making food science accessible to all. Discover premium ingredients, expert resources, and free formulation tools at capecrystalbrands.com/tools. — Ed |

Enjoyed this post? Subscribe to The Crystal Scoop

Food-science tips, ingredient know-how, and recipes. No spam—unsubscribe anytime.

- Choosing a selection results in a full page refresh.