The Complete History of Xanthan Gum: From Accidental Discovery to Global Industry Standard

SUBSCRIBE TO OUR BLOG

Promotions, new products, and recipes.

Few food additives have transformed as many industries as xanthan gum. This remarkable polysaccharide, discovered in a laboratory in the late 1950s, has become an essential ingredient in everything from salad dressings and gluten-free baked goods to oil drilling fluids and cosmetics. Its journey from scientific curiosity to global industry standard reveals a fascinating chapter in the intersection of food science, microbiology, and industrial innovation. This comprehensive exploration traces the complete history of xanthan gum, from its serendipitous discovery to its current status as one of the most versatile and widely used hydrocolloids in the world.

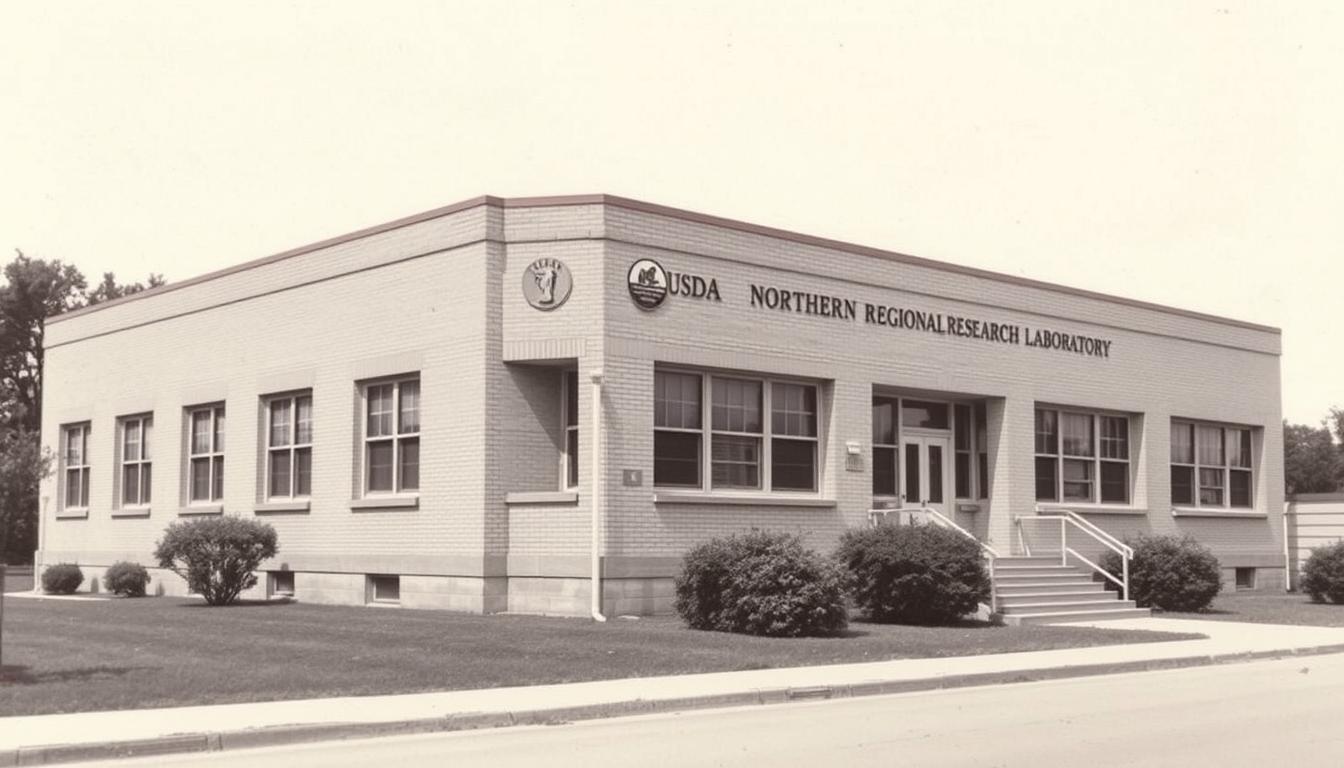

The Discovery and Early Development of Xanthan Gum

The story of xanthan gum begins in the late 1950s at the United States Department of Agriculture's Northern Regional Research Laboratory (NRRL) in Peoria, Illinois. A team of microbiologists led by Dr. Allene Rosalind Jeanes was conducting extensive research on bacterial polysaccharides as part of a broader program to find new applications for agricultural products.

Dr. Jeanes and her team were studying the bacterium Xanthomonas campestris, a plant pathogen that causes black rot in cruciferous vegetables like cabbage and cauliflower. They observed that this bacterium produced a unique slimy substance when grown on a carbohydrate medium. This substance, later named xanthan gum after the bacterium that produces it, demonstrated remarkable thickening, stabilizing, and suspending properties.

What made this discovery particularly significant was that unlike many other thickening agents, xanthan gum maintained its viscosity across a wide range of temperatures, pH levels, and salt concentrations. It also exhibited pseudoplastic or "shear-thinning" behavior, becoming less viscous when subjected to shear forces (like stirring or pouring) and returning to its original viscosity when at rest.

Commercialization and Early Applications

Industrial fermentation tanks used for early commercial production of xanthan gum in the 1960s

The commercial journey of xanthan gum began in 1961 when Kelco Company (now part of CP Kelco) obtained an exclusive license from the USDA to produce and market xanthan gum under the brand name "Kelzan." This marked the beginning of industrial-scale production of this unique polysaccharide.

The production process developed during this period remains fundamentally similar to methods used today. It involves fermenting Xanthomonas campestris in a medium containing glucose or sucrose, along with other nutrients. After fermentation, the xanthan gum is recovered through precipitation with isopropyl alcohol, then dried and milled into a fine powder.

The food industry was the first to embrace xanthan gum's potential. Its ability to stabilize emulsions made it perfect for salad dressings, preventing oil and water separation while maintaining a smooth, pourable consistency. Early adopters also included sauce manufacturers who valued xanthan gum's ability to suspend particles and provide a consistent texture.

"The discovery of xanthan gum represents one of the most successful transfers of technology from government research to commercial application in the history of food additives."

Regulatory Approval and Global Adoption

The FDA headquarters where xanthan gum received approval as a food additive in 1969

A critical milestone in xanthan gum's history came in 1969 when the U.S. Food and Drug Administration (FDA) approved it as a food additive. This approval followed extensive toxicological testing that verified its safety for human consumption. The FDA classified xanthan gum as "Generally Recognized As Safe" (GRAS), opening the door for widespread adoption in the American food industry.

International regulatory approvals soon followed. The Joint FAO/WHO Expert Committee on Food Additives (JECFA) evaluated xanthan gum in 1974 and established an "Acceptable Daily Intake (ADI) not specified," their highest safety category. The European Economic Community (now European Union) approved xanthan gum in 1980, designating it with the E number E415.

By the mid-1970s, xanthan gum had gained regulatory approval in most major markets worldwide, including Canada, Japan, and Australia. This global regulatory acceptance accelerated its adoption across diverse industries and applications.

| Year | Regulatory Body | Approval/Designation |

| 1969 | U.S. Food and Drug Administration (FDA) | Approved as food additive; GRAS status |

| 1974 | Joint FAO/WHO Expert Committee (JECFA) | ADI "not specified" (highest safety category) |

| 1980 | European Economic Community | Approved as E415 |

| 1976-1982 | Canada, Japan, Australia | Approved for food use |

Expanding Applications Across Industries

The diverse range of products containing xanthan gum across multiple industries

Throughout the 1970s and 1980s, xanthan gum's applications expanded dramatically beyond its initial use in salad dressings. The food industry found increasingly diverse uses for this versatile ingredient, incorporating it into sauces, gravies, dairy products, and frozen foods. Its ability to prevent ice crystal formation made it particularly valuable in frozen desserts, while its stabilizing properties improved the texture and shelf life of baked goods.

A significant breakthrough came in the oil industry during the 1970s energy crisis. Engineers discovered that xanthan gum solutions were ideal for enhanced oil recovery and as a component in drilling muds. Its pseudoplastic properties allowed drilling fluids to flow easily when pumped but gel when static, effectively suspending drill cuttings. This application dramatically increased demand for xanthan gum and spurred investment in production capacity.

The pharmaceutical and cosmetic industries also began incorporating xanthan gum into their formulations. In pharmaceuticals, it served as a suspending agent for oral medications and as a binding agent in tablets. The cosmetics industry valued its ability to stabilize emulsions and provide a smooth, consistent texture in lotions, creams, and other personal care products.

Food Industry

- Salad dressings and sauces

- Dairy products and ice cream

- Gluten-free baked goods

- Beverages and drink mixes

- Frozen foods and desserts

Industrial Applications

- Oil drilling fluids

- Enhanced oil recovery

- Agricultural formulations

- Textile printing pastes

- Ceramic glazes and paints

Personal Care & Pharmaceuticals

- Creams and lotions

- Toothpaste and oral care

- Pharmaceutical suspensions

- Tablet binding agents

- Controlled-release formulations

The Gluten-Free Revolution and Modern Production

Modern gluten-free baked goods that maintain their structure and texture thanks to xanthan gum

The early 2000s saw a dramatic increase in demand for xanthan gum with the rise of the gluten-free movement. As celiac disease awareness grew and gluten-free diets gained popularity, food manufacturers faced the challenge of creating gluten-free products with acceptable texture and mouthfeel. Xanthan gum emerged as a crucial ingredient in this revolution.

In gluten-free baking, xanthan gum performs many of the functions normally provided by gluten. It creates elasticity and structure in doughs, traps air bubbles in batters, and provides the cohesive texture that would otherwise be missing. This application significantly expanded the retail market for xanthan gum, making it a common pantry item for home bakers with gluten sensitivities.

Modern production of xanthan gum has evolved to meet this growing demand. Today's manufacturing processes focus on consistency, purity, and sustainability. Advanced fermentation technologies have improved yields and reduced production costs, while purification methods have been refined to meet stringent quality standards for various applications.

The global xanthan gum market has grown substantially, with annual production exceeding 100,000 metric tons. Major producers have established facilities across North America, Europe, and Asia to serve regional markets. China has emerged as a significant producer, introducing new competition and driving innovation in production methods.

Research Breakthroughs and Recent Innovations

Modern scientific research continues to explore xanthan gum's molecular structure and potential applications

Scientific understanding of xanthan gum has advanced significantly since its discovery. Researchers have elucidated its complex molecular structure, consisting of a cellulose backbone with trisaccharide side chains composed of mannose, glucuronic acid, and a terminal mannose unit. This unique structure explains many of xanthan gum's remarkable properties.

Recent research has focused on modifying xanthan gum's properties for specific applications. Scientists have developed methods to control its molecular weight, degree of acetylation, and pyruvate content, allowing for customized versions with different viscosity profiles, thermal stability, and compatibility with other ingredients.

Sustainability has become a major focus in xanthan gum production. Manufacturers have developed processes using agricultural waste products as fermentation feedstocks, reducing reliance on food-grade glucose or sucrose. Water recycling systems and energy-efficient fermentation methods have further reduced the environmental footprint of xanthan gum production.

Health researchers have also investigated potential benefits beyond xanthan gum's functional properties. Some studies suggest it may have prebiotic effects, promoting beneficial gut bacteria. Other research has explored its potential to lower blood glucose levels and cholesterol, though more clinical studies are needed to confirm these effects.

Interesting Historical Facts and Anecdotes

Dr. Allene Rosalind Jeanes, the pioneering scientist who led the team that discovered xanthan gum

The discovery of xanthan gum is often cited as one of the most successful examples of government-funded research leading to commercial applications. Dr. Allene Rosalind Jeanes, who led the research team at the USDA, was a pioneering female scientist who made numerous contributions to carbohydrate chemistry, including work on dextran (used in blood plasma extenders) and xanthan gum.

An interesting historical anecdote involves NASA's use of xanthan gum in space missions. In the 1960s and 1970s, NASA incorporated xanthan gum into astronaut foods to prevent ingredient separation in zero-gravity environments. This early adoption helped demonstrate xanthan gum's exceptional stabilizing properties under extreme conditions.

The name "xanthan" derives from the bacterial genus Xanthomonas, which itself comes from the Greek word "xanthos" meaning yellow, referring to the yellowish colonies formed by these bacteria. This naming convention reflects the scientific practice of the era when the gum was discovered.

A curious fact about xanthan gum production is that the same organism that produces this valuable food additive is also a significant plant pathogen. Xanthomonas campestris causes black rot in cruciferous vegetables, resulting in substantial crop losses. This represents a rare case where a plant pathogen has been harnessed for beneficial industrial applications.

Did you know? The first commercial application of xanthan gum was in salad dressings, where it prevented oil and water separation while maintaining a pourable consistency. This single application revolutionized the prepared salad dressing market in the 1960s.

The Enduring Legacy of Xanthan Gum

The global impact of xanthan gum spans multiple industries and continues to grow

From its humble beginnings in a USDA laboratory to its current status as a global industry standard, xanthan gum represents one of the most successful food additives developed in the 20th century. Its journey illustrates how scientific research, industrial innovation, and regulatory cooperation can create products that transform multiple industries.

Today, xanthan gum continues to be an essential ingredient in countless products we encounter daily. Its versatility, functionality, and safety record have ensured its enduring relevance despite the development of numerous other hydrocolloids. As consumer preferences evolve and new applications emerge, xanthan gum's remarkable properties will likely keep it at the forefront of food, pharmaceutical, and industrial formulations for decades to come.

The history of xanthan gum also serves as an inspiring example of how scientific curiosity about a plant pathogen led to discoveries with far-reaching benefits. It reminds us that innovations can come from unexpected sources and that fundamental research can yield practical applications that improve products and processes across diverse industries.

Deepen Your Food Science Knowledge

Want to learn more about food additives and their fascinating histories? Subscribe to our newsletter for regular updates on food science, ingredient technology, and the stories behind everyday food components.

Frequently Asked Questions About Xanthan Gum

When was xanthan gum first discovered?

Xanthan gum was first discovered in the late 1950s by researchers at the USDA Northern Regional Research Laboratory in Peoria, Illinois. The research team was led by Dr. Allene Rosalind Jeanes, who was studying bacterial polysaccharides.

Why is it called xanthan gum?

The name "xanthan gum" comes from the bacterium that produces it, Xanthomonas campestris. The genus name Xanthomonas itself derives from the Greek word "xanthos" meaning yellow, referring to the yellowish colonies formed by these bacteria.

When did xanthan gum become commercially available?

Commercial production of xanthan gum began in 1961 when Kelco Company (now part of CP Kelco) obtained an exclusive license from the USDA to produce and market it under the brand name "Kelzan." It became more widely available after receiving FDA approval as a food additive in 1969.

What was the first commercial application of xanthan gum?

The first major commercial application of xanthan gum was in salad dressings, where it prevented oil and water separation while maintaining a pourable consistency. This application revolutionized the prepared salad dressing market in the 1960s.

|

About the Author Ed is the founder of Cape Crystal Brands, editor of the Beginner’s Guide to Hydrocolloids, and a passionate advocate for making food science accessible to all. Discover premium ingredients, expert resources, and free formulation tools at capecrystalbrands.com/tools. — Ed |

Enjoyed this post? Subscribe to The Crystal Scoop

Food-science tips, ingredient know-how, and recipes. No spam—unsubscribe anytime.

- Choosing a selection results in a full page refresh.