Introduction

Hydroxypropyl Methylcellulose (HPMC), also called Hypromellose, is a plant-derived cellulose ether valued for thickening, stabilizing, film-forming, and heat-gelation. It’s widely used in plant-based meats, gluten-free baking, sauces, foams, and also in pharmaceuticals for capsules and controlled release.

Quick Answers About HPMC

Is HPMC safe to consume?

Yes. HPMC is widely used in both food and pharmaceuticals and is considered safe within regulatory limits.

Does all HPMC gel when heated?

No. Only certain substitution levels (hot-set grades) create thermal gels. Others function mainly as thickeners or stabilizers.

Is HPMC vegan and gluten-free?

Yes. It’s plant-derived, allergen-free, and works well in vegan and gluten-free foods.

What’s the difference between HPMC and methylcellulose?

HPMC is methylcellulose modified with hydroxypropyl groups, which improves solubility and flexibility. Many culinary functions overlap between the two.

How much HPMC should I use?

Typical usage is 0.2–1% for sauces and foams, and 0.5–2% for doughs or plant-based meats, depending on grade and process.

What is HPMC?

HPMC is cellulose that’s been modified with methyl and hydroxypropyl groups. This makes it cold-water soluble, able to build viscosity, stabilize emulsions/foams, form clear films, and—depending on grade—gel when heated then melt on cooling (thermal gelation).

How is HPMC Made?

- Cellulose Prep: Purified cellulose (wood pulp or cotton) is alkalized.

- Etherification: Reacted with methyl chloride and propylene oxide to add methyl and hydroxypropyl groups.

- Purification & Drying: Washed, neutralized, dried, and milled to specific viscosities/gel temps.

Culinary Uses of HPMC

- Plant-Based Meats: Hot-set gels hold shape and juiciness during cooking.

- Gluten-Free Baking: Improves dough elasticity, gas retention, and crumb.

- Sauces & Dressings: Adds body and stabilizes emulsions.

- Foams & Films: Stabilizes foams; makes glossy edible coatings.

- Freeze/Thaw Help: Certain grades reduce syneresis and ice crystal growth.

Benefits & Functional Properties

- Thermal Gelation (select grades): Heat-set gels that reverse on cooling.

- Cold-Water Soluble: Easy hydration and viscosity build.

- Clean Taste & Clarity: Neutral flavor with clear solutions/films.

- Versatile pH/Process: Performs across broad pH and processing conditions.

- Plant-Based, Allergen-Friendly: Suitable for vegan and gluten-free labels.

Usage Tips & Starter Rates

- Disperse Dry: Premix with sugar or other powders; sprinkle into vigorous mixing.

- Hydration: Use cold water for best solubility; allow 5–10 minutes.

- Starter Use Levels: 0.2–1.0% in sauces/foams; 0.5–2.0% in gluten-free doughs; plant-based meats vary by grade.

- Select the Right Grade: Choose viscosity and gel temperature to match your process.

Where to Buy HPMC

Find premium HPMC and companion hydrocolloids for R&D, culinary, and production use at Cape Crystal Brands.

👉 Shop HPMC Now

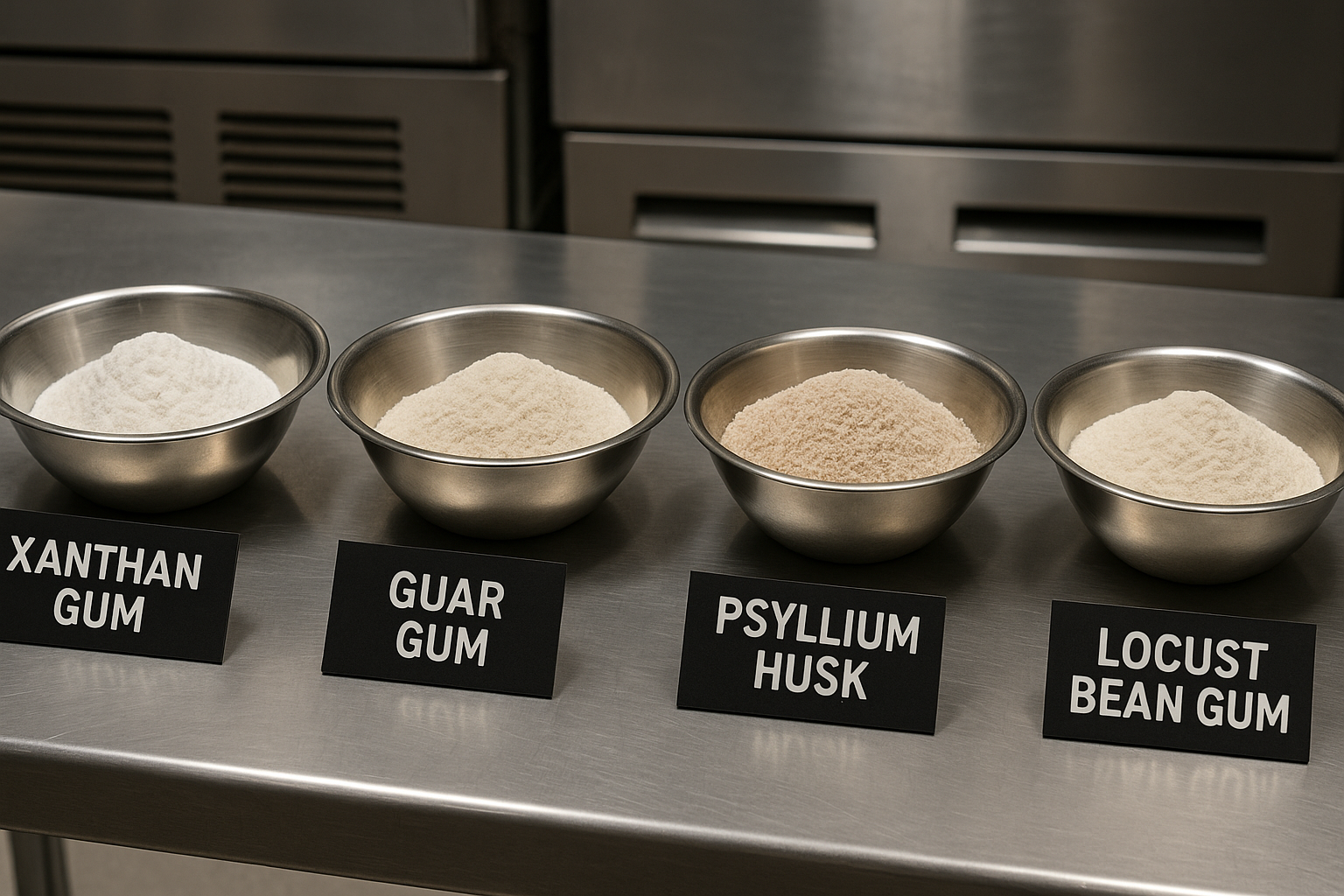

Related Functional Additives

Check out other ingredients used for emulsifying, stabilizing, or improving food structure:

Frequently Asked Questions (FAQs)

Is HPMC safe to consume?

Yes. It’s widely accepted for food and pharmaceutical use when applied within regulatory limits.

Does all HPMC gel when heated?

No. Thermal gelation depends on grade/substitution level. Choose a hot-set grade for heat gelling.

Is HPMC vegan and gluten-free?

Yes. It’s plant-derived and free from gluten and common allergens.

What’s the difference between HPMC and methylcellulose?

HPMC is methylcellulose further modified with hydroxypropyl groups, improving solubility and flexibility; many culinary behaviors overlap.

Typical usage levels?

Start at 0.2–1.0% for sauces/foams and 0.5–2.0% for doughs/plant-based meats; optimize by grade and process.

Keep Learning with Cape Crystal Brands