Hydrocolloids in Dairy: How They Keep Your Ice Cream Creamy and Yogurt Perfect

SUBSCRIBE TO OUR BLOG

Promotions, new products, and recipes.

What makes your ice cream silky smooth and your yogurt perfectly thick? The answer lies in hydrocolloids—nature’s secret stabilizers! Used in dairy for thickening, gelling, and preventing ice crystals, hydrocolloids like carrageenan and guar gum ensure the perfect mouthfeel in your favorite dairy products. In this guide, we’ll explore how they work and why they’re essential for dairy quality!

Hydrocolloids in food science refer to a diverse group of substances that are added to food formulations to achieve specific functional properties. These substances can be extracted from natural sources or produced through chemical synthesis, and each one has unique properties that make it suitable for different food applications.

In this article, we will explore the importance of hydrocolloids in food science and technology, their different types, and how they are used in food processing. We will also discuss the benefits of using hydrocolloids and their future in the food industry.

Key Takeaways:

- Hydrocolloids play a crucial role in enhancing food texture, stability, and flavor in modern food science data-mce-fragment="1"> and technology.

- There are different types of hydrocolloids that are extracted from natural sources or produced through chemical synthesis, each with unique properties suitable for different food applications.

- Hydrocolloids contribute to product stability, texture enhancement, and flavor release, resulting in overall consumer satisfaction.

- Emerging trends and technologies may further enhance the role of hydrocolloids in food processing and product development in the future.

Understanding Hydrocolloids and Their Types

Hydrocolloids are a diverse group of polysaccharides and proteins that have the ability to form gels or thicken solutions when mixed with water. These ingredients have become increasingly popular in modern food science and technology due to their unique properties and versatility.

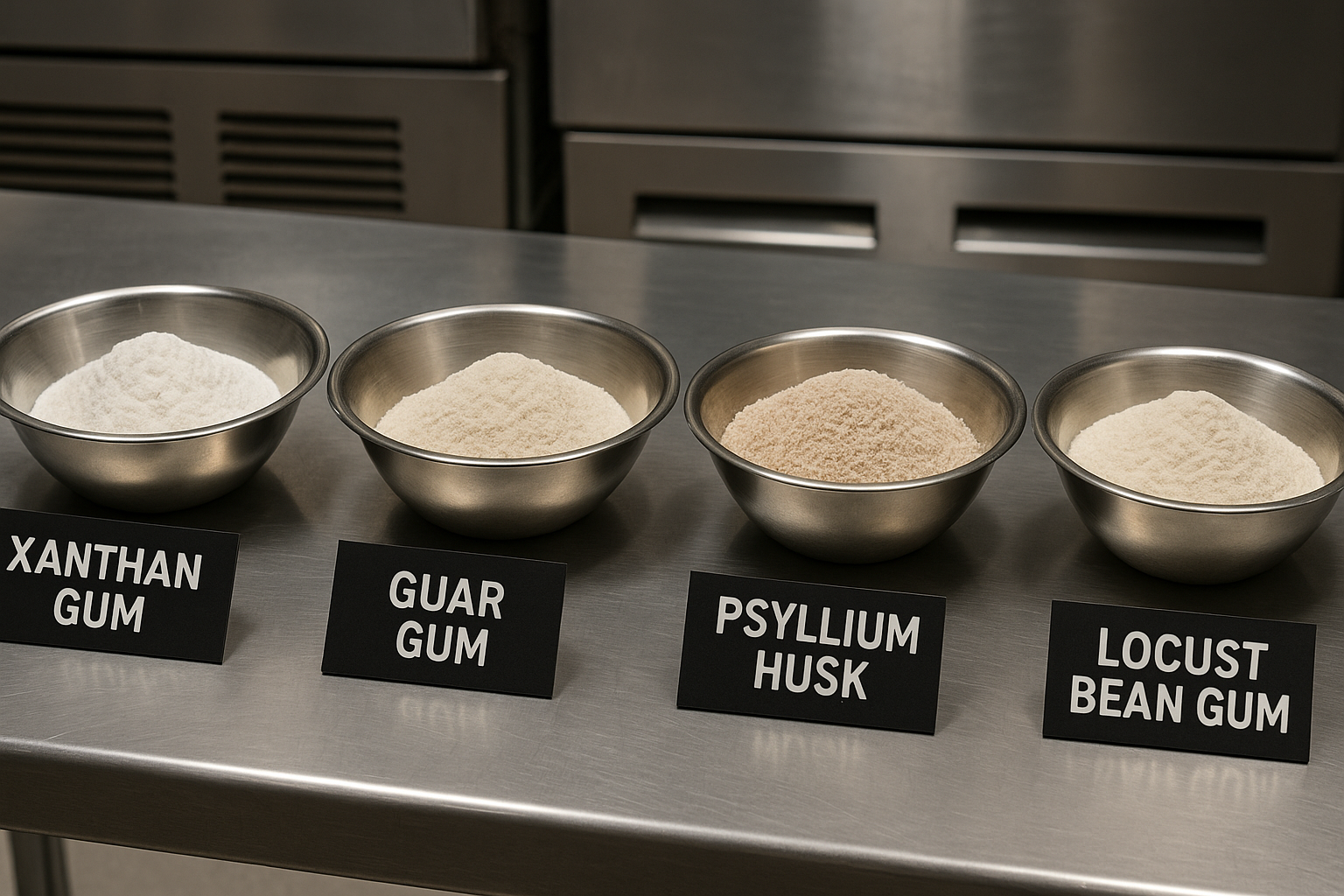

There are many different types of hydrocolloids, each with its own set of characteristics and applications. Some of the most commonly used hydrocolloids in food formulation include:

| Hydrocolloid | Origin | Form | Applications |

|---|---|---|---|

| Agar agar | Seaweed | Powder | Used as a gelling agent in desserts, confectionery, and bakery products. |

| Alginates | Brown Seaweeds | Powder, Gel | Used to create firm, uniform gels, and to thicken liquids. Commonly used in the production of dairy products, meats, and sauces. |

| Carrageenan | Red Seaweeds | Powder | Used to thicken, bind, and stabilize dairy products, processed meats, and sauces. |

| Guar Gum | Legume Seeds | Powder | Used as a thickening agent and to improve the texture of baked goods, dairy products and sauces. |

| Xanthan Gum | Bacteria (Xanthomonas campestris) | Powder | Used to thicken, emulsify and stabilize liquid-based products such as salad dressings, sauces, and beverages. |

Hydrocolloids are used in a wide range of food products, including baked goods, processed meats, dairy products, sauces, and beverages. They can be used to modify texture, improve viscosity, and enhance mouthfeel.

Hydrocolloids can also improve the stability of food products by preventing separation, controlling water activity, and extending shelf life. In the next section, we will explore the importance of hydrocolloids in food processing and how they contribute to product stability.

The Importance of Hydrocolloids in Food Processing

Hydrocolloids play a crucial role in food processing, contributing to the overall quality and stability of food products. These natural or synthetic polymers are essential in creating the desired texture, viscosity, and flavor of a wide range of food items, from ice cream to soups to bakery products.

The importance of hydrocolloids lies in their ability to maintain the quality and consistency of food products throughout the manufacturing process. Hydrocolloids can improve product stability by preventing the separation of ingredients, controlling water activity, and reducing the risk of microbial growth.

Moreover, hydrocolloids are vital in maintaining the texture of food products. They can create gels, thicken and emulsify, and even stabilize foam. A well-designed product with the right hydrocolloid formulation can result in a smooth, creamy consistency in ice creams, or a rich, velvety texture in sauces.

Hydrocolloids are also useful in modifying the taste and flavor profile of food products. They work by interacting with taste molecules and can produce enhanced flavor release, resulting in a more enjoyable eating experience.

Examples of Hydrocolloids in Food Processing

| Hydrocolloid Type | Application |

|---|---|

| Guar Gum | Thickening and stabilizing agent in soups, sauces, and bakery products |

| Carrageenan | Thickening and gelling agent in dairy products, such as ice cream |

| Pectin | Gelling agent in jellies, jams, and fruit preserves |

| Xanthan Gum | Stabilizing agent in salad dressings, sauces, and bakery products |

As seen in the table above, hydrocolloids are used in a wide range of food products. Each type of hydrocolloid has unique properties that make them suitable for different applications, highlighting the versatility of hydrocolloid technology in food science.

Overall, the importance of hydrocolloids in food processing cannot be overstated. From enhancing texture and flavor to maintaining product stability, hydrocolloids have revolutionized the way we produce and consume food products.

Enhancing Food Texture with Hydrocolloids

Hydrocolloids play a crucial role in enhancing the texture of food products. They are capable of modifying viscosity, creating gels, and improving mouthfeel, resulting in a more enjoyable eating experience.

For example, adding hydrocolloids like pectin to fruit-based products can create a gel-like texture, providing a more pleasant texture and mouthfeel. Similarly, adding carrageenan to dairy products like ice cream can create a smoother, creamier texture that also helps prevent ice crystal formation.

Hydrocolloids can also be used to create unique textures in products like meat and plant-based alternatives. For example, adding hydrocolloids to meat products can create juiciness and tenderness, while also helping maintain product stability and integrity during cooking processes.

When formulating with hydrocolloids, factors like concentration, processing steps, and pH levels must be taken into consideration to achieve the desired texture and mouthfeel.

Hydrocolloid-Based Texturizers

Hydrocolloid-based texturizers are commonly used in the food industry to enhance texture. These texturizers can create a range of textures, from soft and tender to firm and chewy.

| Hydrocolloid | Texture Characteristics | Applications |

|---|---|---|

| Agar agar | Firm, brittle, can withstand high temperatures and acidic conditions | Baked goods, confectionery, desserts |

| Guar Gum | Thickens, imparts smoothness and creaminess, can withstand high heat | Beverages, dairy products, processed fruits and vegetables |

| Xanthan Gum | Increases viscosity, creates a creamy and smooth texture, enhances mouthfeel | Dressings, sauces, bakery products, frozen desserts |

Texturizers like these can help improve product stability and shelf life, while also providing a more pleasing sensory experience for consumers.

The Future of Hydrocolloids in Food Texture

The use of hydrocolloids in food texture is a rapidly growing field. With the rise of plant-based and alternative protein products, there is an increasing need for innovative solutions that can create the same textures and mouthfeel as traditional meat products.

There is also a growing interest in creating new and unique textures in other product categories like baked goods and confectionery. As hydrocolloid technology continues to evolve, we can expect to see more exciting developments in the application of hydrocolloids in food texture in the years to come.

Hydrocolloids and Food Flavor

In the food industry, hydrocolloids play a crucial role in enhancing food flavor, making it more enjoyable and satisfying for consumers. Hydrocolloids can interact with taste molecules in the food matrix, leading to better flavor release.

For example, in dairy products such as ice cream, hydrocolloids like guar gum and carrageenan can help prevent the formation of ice crystals and improve the texture of the product. This enhances the flavor by creating a smoother, creamier mouthfeel.

Hydrocolloids also contribute to the stability of flavors in foods. In acidic products like fruit juices, pectin and xanthan gum can help keep the fruit particles suspended in the juice, preventing them from sinking to the bottom. This ensures that the flavors are evenly distributed throughout the product, providing a consistent taste experience with every sip.

"Hydrocolloids play a crucial role in enhancing food flavor, making it more enjoyable and satisfying for consumers."

The role of hydrocolloids in flavor enhancement is particularly important for low-fat or low-sugar products, as these products can often lack the rich, full flavor of their higher fat or sugar counterparts. Hydrocolloids can help compensate for this by providing a more satisfying taste experience without the added calories.

Overall, hydrocolloids are an essential ingredient in the food industry, contributing not only to product stability and texture but also to flavor enhancement. Their unique properties make them ideal for a wide range of food applications, and their continued use is sure to drive innovation and advancements within the industry.

The Importance of Hydrocolloids in Improving Food Stability

Hydrocolloids are well-known for their vital role in improving food stability. They help to maintain the physical and chemical properties of food by preventing phase separation, controlling water activity, and reducing syneresis. Hydrocolloids are effective in stabilizing different types of food systems, including dressings, sauces, and beverages.

Preventing Phase Separation

Phase separation is a common problem in food processing, where the components of a food product separate due to changes in temperature, pressure, or mechanical stress. Hydrocolloids can prevent phase separation by stabilizing the interface between the different phases of the food product. This leads to a more consistent and stable product with a longer shelf life.

Controlling Water Activity

Hydrocolloids can also control water activity in food by interacting with water molecules. This is particularly important in preventing microbial growth, which can cause spoilage. By controlling water activity, hydrocolloids help to maintain the quality and safety of food, leading to increased consumer satisfaction.

Reducing Syneresis

Syneresis refers to the separation of liquid from a gel-like substance. This is a common issue in food products that contain a high amount of water. Hydrocolloids can reduce syneresis by absorbing excess water and stabilizing the gel structure of the food product. This leads to a more visually appealing and stable product with a longer shelf life.

"Hydrocolloids are effective in stabilizing different types of food systems, including dressings, sauces, and beverages."

In conclusion, hydrocolloids play a crucial role in improving food stability. They help to prevent phase separation, control water activity, and reduce syneresis, leading to a more consistent and stable product with a longer shelf life. Incorporating hydrocolloids in food processing can result in a more high-quality end product, increased consumer satisfaction, and reduced food waste.

Hydrocolloid Technology and Innovations

Hydrocolloids have been an integral part of the food industry for many years. However, with the advent of modern food science, hydrocolloid technology has seen significant innovations in recent times. Today, hydrocolloids are used in ways that were once unimaginable, making it an exciting time for food technologists and consumers alike.

The use of hydrocolloid technology has not only improved food texture, flavor, and stability but has also opened up new possibilities in food product development. By leveraging the unique properties of hydrocolloids, food manufacturers can create products with improved sensory properties and extended shelf life.

One example of hydrocolloid innovation is the development of hydrocolloid-based encapsulation techniques. These methods involve encapsulating active ingredients such as flavors, nutrients, and colors within a hydrocolloid matrix. This technology helps to protect these sensitive ingredients from degradation and improves their stability in food products.

Another area of innovation in hydrocolloid technology is the use of hybrid hydrocolloids. These are blends of different hydrocolloids that provide unique functional properties, making them ideal for specific food applications. For example, a hybrid hydrocolloid of xanthan gum and carrageenan can provide improved gelling properties, and is particularly useful in the production of low-fat food products.

Hydrocolloid Technology in Meat Processing

The use of hydrocolloid technology in meat processing has also seen significant advancements in recent years. Hydrocolloids such as carrageenan, alginate, and collagen are used to improve the texture and appearance of meat products. These hydrocolloids can be used to retain moisture, increase yield, and prevent syneresis, resulting in a juicier, more appealing end product.

In addition to improving the texture and appearance of meat products, hydrocolloid technology can also be used to reduce the amount of fat and sodium in these products. Hydrocolloids can be used as fat replacers, and can also be used to replace sodium, resulting in healthier meat products without sacrificing taste or texture.

Hydrocolloid Technology in Plant-Based Products

The growing popularity of plant-based products has also led to innovation in hydrocolloid technology. Hydrocolloids such as carrageenan, xanthan gum, and pectin are commonly used in plant-based products to improve texture and stability. These hydrocolloids can be used to create vegan meat alternatives, dairy-free cheese, and other plant-based products that mimic the texture and flavor of their animal-based counterparts.

Moreover, hydrocolloids can also be used to enhance the nutritional profile of plant-based products. This can be achieved by adding hydrocolloids that are high in fiber, such as inulin or psyllium husk.

The Benefits of Hydrocolloids in Food Science

Hydrocolloids are an essential ingredient in modern food science. Here are some of the key benefits of using hydrocolloids in food formulations:

- Product Stability: Hydrocolloids can improve the stability and shelf life of food products by preventing phase separation and controlling water activity. This is particularly important in processed foods where stability is a critical factor.

- Texture Enhancement: Hydrocolloids can modify the viscosity of food products, create gels, and improve mouthfeel. This is especially important in foods that require a specific texture, such as ice cream or sauces.

- Flavor Release: Hydrocolloids can interact with taste molecules, improving flavor release and creating a more enjoyable eating experience. This is important in food products where flavor is a critical factor, such as soups and sauces.

- Improved Nutrition: Hydrocolloids can also be used to replace fat and sugar in food formulations, making products healthier and more appealing to health-conscious consumers.

Overall, hydrocolloids offer a range of benefits that make them an essential ingredient in the food industry. By improving stability, texture, flavor, and nutrition, hydrocolloids help create products that meet the needs and expectations of today's consumers.

Hydrocolloids in Food Industry Applications

Hydrocolloids have become ubiquitous in the food industry due to their unique properties. Their wide range of applications makes them an essential ingredient in various food products.

One of the most common uses for hydrocolloids in the food industry is in thickening and gelling. Hydrocolloids such as agar, carrageenan, and guar gum are used extensively in the production of jellies, jams, and sauces. They are also used in dairy products such as yogurt and cheese to improve texture, yield, and stability.

| Hydrocolloid | Food Product |

|---|---|

| Agar | Jellies, puddings, canned meats, bakery fillings |

| Carrageenan | Ice cream, chocolate milk, processed cheese, plant-based milk alternatives |

| Guar Gum | Baked goods, fruit juices, salad dressings, sauces |

Hydrocolloids also play a vital role in controlling water activity, which helps to improve product stability and shelf life. They prevent ice crystal formation in frozen foods, which can cause freezer burn and spoilage.

Lastly, hydrocolloids are used to create emulsions and suspensions in food products. They help to stabilize the mixture by preventing separation and maintaining a consistent texture. Emulsifiers such as carrageenan and lecithin are commonly used in bakery products, ice cream, and salad dressings.

As the food industry continues to evolve, hydrocolloids will remain a crucial ingredient in the development of new products and food processing techniques. Their unique properties and versatility make hydrocolloids an essential ingredient in modern food science.

Hydrocolloid Insights for Food Technologists

Hydrocolloid technology has transformed the food industry, offering new ways to create and improve food products. To effectively utilize hydrocolloids in food science, food technologists must take into account several factors.

Best Practices

When working with hydrocolloids, it's crucial to understand their unique properties and how they interact with other ingredients. For example, some hydrocolloids may require specific processing techniques or temperatures to achieve optimal functionality. Food technologists should also consider the sensory aspects of the final product to determine the appropriate hydrocolloid type and amount.

Formulation Considerations

Hydrocolloids can be used in a variety of food formulations, including sauces, dressings, and bakery products. When formulating with hydrocolloids, food technologists should consider the product's desired texture, viscosity, and stability. They should also take into account the shelf life and storage conditions of the final product, as certain hydrocolloids may affect these factors.

Potential Challenges

While hydrocolloids offer many benefits in food science, there are potential challenges that food technologists should be aware of. For example, some hydrocolloids may interact negatively with other ingredients or cause unwanted changes in product texture. Additionally, sourcing high-quality hydrocolloids can be a challenge due to variations in raw material quality and processing methods.

Exploring the Future of Hydrocolloids in Food Science

Hydrocolloids have come a long way in the food industry, and their role is only set to expand in the future. With advancing technology and research, we will witness more innovative applications of hydrocolloids, contributing to modern food science and processing.

The field of hydrocolloid technology is constantly evolving, and food scientists are developing new ways of utilizing them to improve food stability, texture, and flavor. This has resulted in more diverse and sustainable food products that meet environmental and consumer demands.

One of the most promising areas of hydrocolloid research is the use of nanotechnology to enhance their properties. This involves the creation of nanoscale hydrocolloids, which are more effective in improving food quality while reducing waste and cost.

Another trend is the use of plant-based hydrocolloids as a sustainable alternative to animal-derived ones. As consumers become more health-conscious and environmentally aware, plant-based hydrocolloids, such as gums and starches, are gaining popularity in food processing.

Furthermore, hydrocolloids are being incorporated into novel food products, such as 3D printed food and functional foods with added health benefits. These developments have the potential to transform the food industry and shape the future of food.

Overall, hydrocolloids are proving to be valuable ingredients in modern food science and technology, and their future looks bright. By continuing to push the boundaries of hydrocolloid research, we can expect to see more innovative and sustainable food products in the years to come.

Conclusion

Hydrocolloids have become an essential component in modern food science. They offer a wide range of benefits, including enhancing food texture and flavor, improving stability and shelf life, and enabling innovative food products and processes.

Through this article, we have explored the different types of hydrocolloids and their unique properties, as well as their crucial role in food processing and product development. We have highlighted the importance of hydrocolloids in creating high-quality foods that meet the consumers' expectations.

As the food industry continues to evolve and consumer demands shift, hydrocolloid technology will undoubtedly play a critical role in meeting these challenges. This versatile ingredient will continue to drive innovation, enabling new product development that meets consumers' changing needs and preferences.

Overall, hydrocolloids are essential tools for food technologists, enabling them to create high-quality food products that meet consumers' expectations. As this article has demonstrated, the use of hydrocolloids in food science will undoubtedly continue to grow and evolve in the future, driving innovation and enhancing the quality and variety of foods available to consumers.

FAQ

What are hydrocolloids?

Hydrocolloids are substances that have the ability to form viscous or gel-like solutions when combined with water. They are commonly used in the food industry to improve texture, stability, and other properties of food products.

What are the different types of hydrocolloids?

There are various types of hydrocolloids, including gums (such as xanthan gum and guar gum), pectin, carrageenan, and alginate. Each type has unique properties and is suitable for different applications in food science and technology.

How are hydrocolloids used in food processing?

Hydrocolloids play a crucial role in food processing by providing stability, improving texture, and enhancing the overall quality of food products. They can be used to thicken, emulsify, stabilize, and control the water content in various food formulations.

How do hydrocolloids enhance food texture?

Hydrocolloids have the ability to modify the viscosity and create gels, which can improve the texture of food. They help create a smooth and creamy mouthfeel in products like sauces, dressings, and desserts.

What impact do hydrocolloids have on food flavor?

Hydrocolloids can interact with taste molecules and help in the release of flavors, leading to a more flavorful end product. They play a role in enhancing the perception of taste and overall taste experience.

How do hydrocolloids contribute to food stability?

Hydrocolloids can prevent phase separation, control water activity, and extend the shelf life of food products. They help maintain the structural integrity and stability of food formulations, ensuring that they remain consistent and safe for consumption.

What are some innovative uses of hydrocolloids in food technology?

Hydrocolloid technology has led to various innovations in the food industry. It has enabled the creation of plant-based meat alternatives, improved gluten-free products, and innovative texture modifiers. Hydrocolloids continue to inspire new product development and enhance existing ones.

What are the benefits of using hydrocolloids in food science?

The use of hydrocolloids in food science provides numerous benefits. They contribute to product stability, enhance texture, improve flavor release, and ultimately lead to increased consumer satisfaction. Hydrocolloids also offer formulation flexibility and can be tailored to meet specific food processing needs.

What are some common applications of hydrocolloids in the food industry?

Hydrocolloids are widely used in various food applications. They can be found in dairy products, baked goods, beverages, sauces, dressings, and confectionery items. They are also used in low-fat and reduced-sugar products to maintain texture and sensory attributes.

What should food technologists consider when working with hydrocolloids?

Food technologists should consider factors such as dosage, compatibility with other ingredients, processing conditions, and the desired texture and stability goals when working with hydrocolloids. They should also stay updated on the latest research and innovations in hydrocolloid technology.

What does the future hold for hydrocolloids in food science?

The future of hydrocolloids in food science looks promising. With advancements in technology and research, hydrocolloids are expected to play an even bigger role in food processing and product development. They will continue to contribute to the creation of innovative and sustainable food solutions.

|

About the Author Ed is the founder of Cape Crystal Brands, editor of the Beginner’s Guide to Hydrocolloids, and a passionate advocate for making food science accessible to all. Discover premium ingredients, expert resources, and free formulation tools at capecrystalbrands.com/tools. — Ed |

Enjoyed this post? Subscribe to The Crystal Scoop

Food-science tips, ingredient know-how, and recipes. No spam—unsubscribe anytime.

- Choosing a selection results in a full page refresh.