Understanding How Brix Effects Hydrodocolloids: A Deep Dive

SUBSCRIBE TO OUR BLOG

Promotions, new products, and recipes.

Brix measurement is an essential tool in the food industry for controlling and maintaining the quality of various food products. In the world of hydrocolloids, Brix concentration plays a crucial role in determining their properties and functionality when used as thickeners, gelling agents, and stabilizers.

Hydrocolloids are polysaccharides or proteins that have the ability to form gels or thick solutions when dispersed in water. To achieve optimal hydrocolloid performance, food scientists must consider the impact of Brix measurements on their behavior.

Key Takeaways

- Brix measurement is essential in controlling and maintaining the quality of food products.

- Brix concentration plays a critical role in determining the properties and functionality of hydrocolloids.

- Hydrocolloids are polysaccharides or proteins that function as thickeners, gelling agents, and stabilizers in various food applications.

- Understanding the interplay between Brix measurements and hydrocolloid behavior is crucial for optimal hydrocolloid performance.

- In this article, we will explore the relationship between Brix and hydrocolloid properties data-mce-fragment="1"> and its impact on food science and everyday diet.

What Are Hydrocolloids?

Hydrocolloids are substances that have the ability to thicken, gel, and stabilize food products. They are widely used in the food industry to improve product texture, consistency, and shelf life. Hydrocolloids are typically added in small amounts to food formulations, but they have a significant impact on the final product properties.

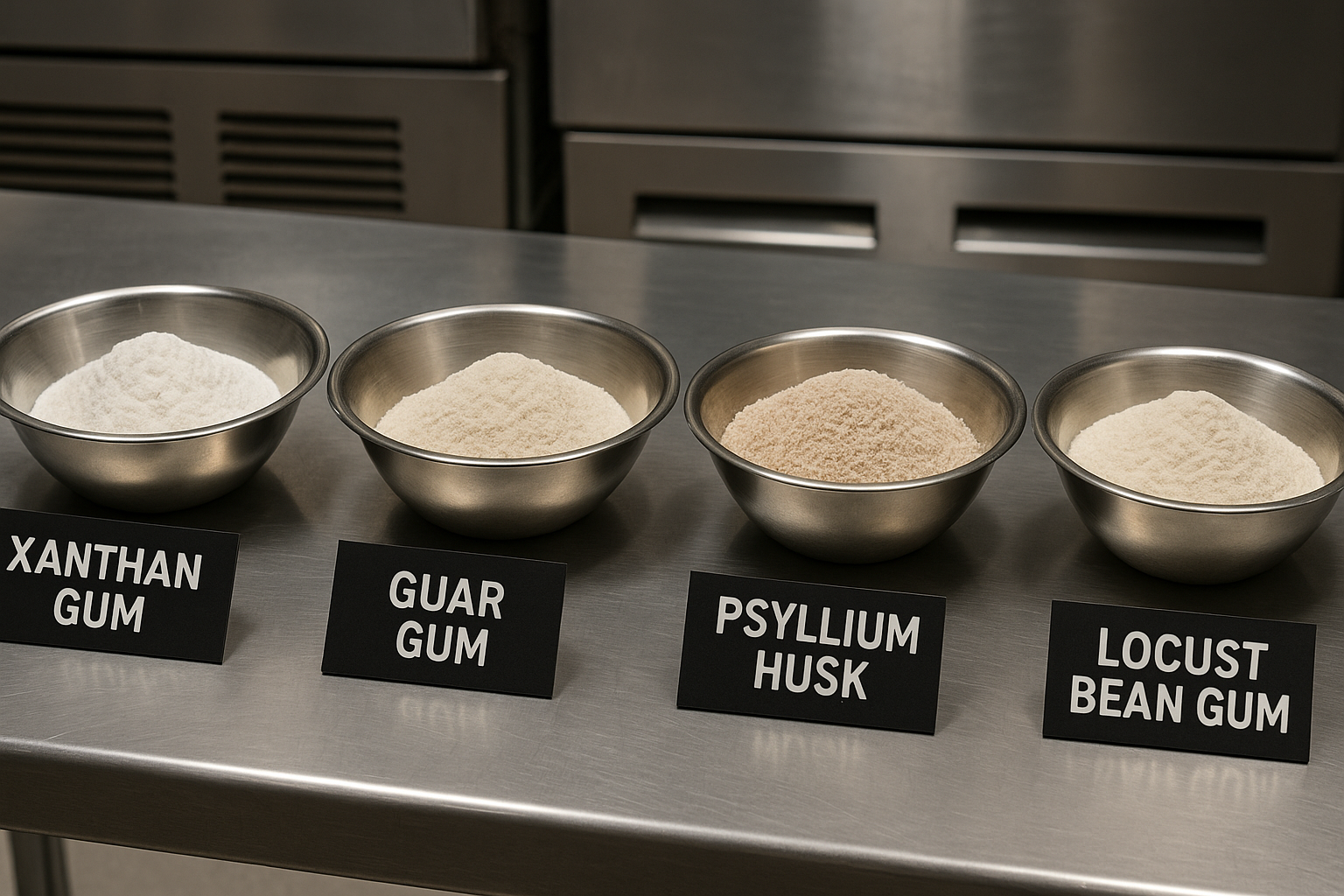

Hydrocolloids can be extracted from various sources such as plants, animals, and microbial organisms. Some common hydrocolloids include agar, alginate, carrageenan, pectin, and xanthan gum. They are categorized based on their unique chemical and physical properties, which determine their functionality in food systems.

Hydrocolloids function as thickeners by increasing the viscosity and consistency of food products. They also serve as gelling agents by forming a stable gel network within a food matrix. This gel network helps to maintain the structural integrity of the food product and prevent the separation of ingredients. Hydrocolloids can also act as stabilizers by preventing the formation of ice crystals in frozen foods and inhibiting the growth of bacteria and microorganisms in perishable food products.

The Basics of Brix Measurement

In the realm of food science, Brix refers to the concentration of dissolved solids in a solution. Brix measurement is typically expressed as a percentage and is used to determine the sweetness and ripeness of fruits, vegetables, and juices. In the context of hydrocolloids, Brix concentration plays a vital role in the behavior of these substances.

Hydrocolloids are complex polymers that interact with water to form gels, thicken solutions, and stabilize emulsions. The presence of Brix can significantly impact the properties and functionality of hydrocolloids. As the concentration of Brix increases, the behavior of hydrocolloids may change in response.

Understanding the relationship between Brix and hydrocolloid behavior is essential to develop precise and effective formulations for the food industry. The effect of Brix on hydrocolloids varies depending on the specific type of hydrocolloid and the Brix concentration level.

In summary, Brix measurement is a crucial factor when working with hydrocolloids. It is essential to consider the impact of Brix concentration on the performance and characteristics of hydrocolloids in food applications.

Understanding Hydrocolloid Properties

Hydrocolloids are known for their versatile functionality in food applications. The unique properties of hydrocolloids are primarily due to their structural features and composition. Hydrocolloid properties can be classified based on their chemical nature, functional properties, and physical characteristics. The most commonly used hydrocolloids include pectin, agar, carrageenan, xanthan gum, and gellan gum.

The relationship between Brix and hydrocolloid performance is closely linked to their properties. Brix measurements can affect the texture, viscosity, and stability of hydrocolloids. Hydrocolloid properties vary with Brix concentration, which in turn affects their rheological behavior. Therefore, understanding the relationship between Brix and hydrocolloid properties is essential in food formulation and processing.

Hydrocolloid properties are influenced by several factors including their molecular weight, degree of branching, degree of esterification, and ionic charges. The molecular weight of hydrocolloids determines their viscosity and gel strength. Hydrocolloids with higher molecular weights usually have greater viscosity and stronger gelling properties. Branching and esterification degrees affect the solubility and interactions with other food components. Ionic charges determine hydrocolloid behavior in different ionic environments and their interactions with proteins.

Furthermore, physical characteristics such as surface charge, hydration, and molecular conformation also play a vital role in hydrocolloid properties. Hydrocolloids usually have a net negative charge, which influences their interactions with other food components. Hydration depends on the degree of solubility and the presence of water-binding sites. Finally, molecular conformation refers to the way hydrocolloids arrange themselves structurally, which directly impacts their functionality.

The Influence of Brix on Hydrocolloid Functionality

Brix concentration is a vital factor that influences the functionality of hydrocolloids in food applications. The effects of Brix on the characteristics and behavior of hydrocolloids are critical to consider during food processing. As Brix concentration increases, it causes changes in the properties of hydrocolloids, such as viscosity, gelation, and stability.

The level of Brix has a direct impact on hydrocolloid characteristics. For instance, at low Brix levels, hydrocolloids tend to have low viscosity and reduced stability. Conversely, at high Brix levels, hydrocolloids exhibit high viscosity, resulting in thick and gel-like textures with improved stability. Therefore, understanding the interplay between Brix levels and the properties of hydrocolloids is fundamental in food science.

Additionally, the impact of Brix on the functionality of hydrocolloids depends on the specific hydrocolloid and food application. Some hydrocolloids may be affected differently by changes in Brix concentration than other hydrocolloids. Therefore, a comprehensive understanding of individual hydrocolloids and their relationship with Brix is essential for achieving optimal functionality in hydrocolloid-based food formulations.

Applications of Hydrocolloids in Food Industry

Hydrocolloids find extensive application in the food industry due to their versatile functional properties. They are commonly used as emulsifiers, thickeners, stabilizers, and gelling agents in various food products. The widespread use of hydrocolloids has led to the development of innovative food products with unique textures and improved sensory characteristics.

Hydrocolloids are used in a wide range of food products, including dairy products, bakery items, meat products, sauces, dressings, and beverages. They are also employed in the production of low-fat and reduced-calorie food products.

The use of hydrocolloids in the food industry has significantly impacted the quality and stability of food products. They contribute to the enhanced texture, mouthfeel, and appearance of food products, ensuring their market acceptability and popularity.

The unique properties of hydrocolloids make them a sought-after ingredient in the food industry. They provide the necessary structure and stability to a wide range of food products, enhancing their overall functionality and sensory attributes. Their effectiveness in improving the quality and stability of food products has been well-established in the food industry, making them an essential component of food formulations.

The Role of Brix on Hydrocolloid Stability

One of the key areas affected by Brix levels in hydrocolloids is stability. Hydrocolloids are often used as stabilizers to prevent separation and provide smooth texture in food products. However, varying Brix concentrations can impact the properties of hydrocolloids and affect their ability to stabilize food systems.

The impact of Brix on hydrocolloid stability is complex and depends on various factors. For instance, higher Brix levels can increase the viscosity of hydrocolloid solutions, leading to improved stability. On the other hand, excessive Brix levels can cause hydrocolloids to form weak or unstable gels, which can negatively impact the stability of food products.

The effect of Brix on hydrocolloid properties is also influenced by other factors, such as pH, ionic strength, and temperature. Therefore, it is important to consider the interplay between Brix and these factors when formulating hydrocolloid-based food products.

Understanding the impact of Brix on hydrocolloid stability is crucial in developing food products with extended shelf life and improved sensory properties. By controlling Brix levels and optimizing hydrocolloid properties, food manufacturers can create stable, high-quality products that meet consumer expectations.

Challenges in Brix-controlled Hydrocolloid Formulations

Formulating hydrocolloid-based food products with precise Brix control poses significant challenges in achieving desired functional properties. One of the primary challenges is the inherent complexity of hydrocolloid systems, which makes it challenging to predict the impact of Brix on hydrocolloid properties.

Additionally, several factors can influence the behavior of hydrocolloids, including pH, temperature, and storage conditions. These factors can interact with Brix, making it challenging to achieve consistent hydrocolloid performance across different batches.

Another challenge is scaling up formulations from the lab to commercial production. The properties of hydrocolloids can vary depending on the scale of production, making it difficult to maintain precise Brix control.

To address these challenges, researchers and industry professionals are exploring innovative solutions such as the use of alternative hydrocolloids or modifying processing conditions to achieve precise Brix control. Additionally, the development of advanced analytical tools and modeling approaches can aid in predicting hydrocolloid behavior in different formulations and processing conditions.

Advanced Techniques for Brix Measurement in Hydrocolloid Systems

Accurate Brix measurement is crucial in understanding the behavior of hydrocolloids in food systems. Traditional Brix measurement techniques, such as refractometry, are limited in their ability to measure Brix in complex matrices. Advanced techniques have emerged to overcome these limitations and provide more precise measurements in hydrocolloid systems.

1. Differential Scanning Calorimetry (DSC)

DSC is a thermal analysis technique used to measure the heat flow associated with chemical reactions and phase changes. It has been utilized to measure Brix in hydrocolloid systems, as changes in heat flow correspond to changes in Brix concentration. DSC provides accurate and reproducible measurements, making it a valuable tool in hydrocolloid research and development.

2. Near-Infrared Spectroscopy (NIRS)

NIRS is a non-destructive technique that uses the absorption of near-infrared light to analyze the chemical composition of a sample. It has been successfully applied to measure Brix in hydrocolloid systems, as the absorption characteristics of hydrocolloids are specific to their Brix concentration. NIRS is a fast and reliable technique that can analyze multiple samples simultaneously, making it a valuable tool in the food industry.

3. Ultrasonic Velocity (UV)

UV is a technique that measures the speed of sound waves through a sample. As Brix concentration affects the density and viscosity of hydrocolloid systems, UV can be utilized to measure Brix indirectly. UV provides fast and non-destructive measurements, making it a viable option for in-line quality control in the food industry.

Advanced techniques for Brix measurement in hydrocolloid systems have revolutionized the field of food science. These techniques provide greater accuracy and precision in Brix measurement, leading to better understanding and optimization of hydrocolloids in food applications.

Case Studies: Brix and Hydrocolloids in Real-world Applications

Real-world applications of hydrocolloids demonstrate the influence of Brix on their properties and functionality. Here are a few examples:

"We found that the addition of a specific hydrocolloid to our fruit juice product resulted in improved mouthfeel and flavor release. However, we had to carefully control the Brix level to ensure the hydrocolloid was effective. Otherwise, we encountered issues with viscosity and stability."

- Food Product Development Manager, Fruit Juice Company

This case study highlights the importance of precise Brix control in hydrocolloid-based formulations for achieving the desired texture and stability in fruit juices.

"We were able to reduce the fat content in our dairy-based dessert product by incorporating hydrocolloids. However, we needed to optimize the Brix level to ensure the desired texture and sensory attributes were maintained. This required an iterative process of adjusting hydrocolloid levels and Brix concentration until we achieved the desired result."

- R&D Scientist, Dairy Products Company

For this case study, careful Brix measurement was required to balance the fat reduction benefits of hydrocolloids with the sensory attributes expected in the dairy dessert product.

"Our gluten-free bakery products require the use of hydrocolloids to achieve the desired texture. However, we faced challenges with Brix control due to the use of alternative sweeteners. By testing a range of hydrocolloid types and concentrations, we were able to identify an optimal combination that resulted in consistent product quality."

- Head Baker, Artisan Bakery

In this example, the use of alternative sweeteners introduced new challenges in Brix control for hydrocolloid-based bakery formulations. Innovative testing and optimization of hydrocolloid types and concentrations ultimately solved the issue.

Future Trends and Research Opportunities

The field of Brix and hydrocolloids is rapidly evolving, and there are several promising trends and research opportunities on the horizon.

One area of potential growth is in the development of new hydrocolloid formulations that can withstand high Brix concentrations. This is particularly relevant for the beverage industry, where high sugar levels can impact the stability and texture of the final product.

Another area of focus is on improving the accuracy and precision of Brix measurement techniques. Advancements in technology have enabled the development of new sensors and instrumentation that can provide real-time feedback on Brix levels in complex hydrocolloid systems.

Research is also being conducted on the impact of Brix on the microbiology of hydrocolloid-based food products. Understanding the interplay between Brix and microbial growth is critical for ensuring food safety and extending the shelf life of these products.

Furthermore, there is a growing interest in the use of sustainable and plant-based hydrocolloids, such as agar, carrageenan, and gellan gum. Research is being conducted on how these alternative hydrocolloids perform at different Brix concentrations, and their potential applications in the food industry.

In summary, the future of Brix and hydrocolloids is full of exciting research opportunities and advancements. By gaining a deeper understanding of the relationship between Brix and hydrocolloid properties, we can develop innovative solutions that enhance the taste, texture, and stability of our favorite food and beverage products.

Conclusion

From the above discussion, it is evident that Brix measurement plays a crucial role in understanding the properties and behavior of hydrocolloids in food systems. By controlling Brix levels, the functionality of hydrocolloids can be optimized for specific food applications, resulting in improved product stability, texture, and sensory properties.

Hydrocolloids are widely used in the food industry, and their functionality is highly dependent on Brix levels. Accurate measurement of Brix concentration is imperative to achieve desired hydrocolloid performance, and advanced techniques have been developed to measure Brix in hydrocolloid systems with high precision.

Despite the potential benefits of Brix-controlled hydrocolloid formulations, challenges such as formulation complexity and variability in raw material sources must be overcome to achieve optimal performance. Future research can focus on developing new techniques and approaches to address these challenges and optimize Brix-controlled hydrocolloid formulations.

Summary:

- Brix levels significantly affect the behavior and properties of hydrocolloids in food systems.

- Precise measurement of Brix concentration is essential to achieve desired hydrocolloid performance.

- Hydrocolloids have diverse applications in the food industry, and their functionality is highly dependent on Brix levels.

- Challenges such as formulation complexity and variability in raw material sources need to be addressed for optimal performance of Brix-controlled hydrocolloid formulations.

- Emerging trends and research opportunities in Brix and hydrocolloids can lead to innovative approaches and techniques for improved food product development.

FAQ

How does Brix affect hydrocolloids?

Brix measurement has a direct impact on the behavior and properties of hydrocolloids. The concentration of Brix can influence the functionality, stability, and performance of hydrocolloids in various food applications.

What are hydrocolloids?

Hydrocolloids are substances that have the ability to thicken or gel when they come into contact with water. They play a crucial role in the food industry as they are used as thickening agents and stabilizers in a wide range of food products.

What are the basics of Brix measurement?

Brix is a measurement scale used to determine the concentration of soluble solids in a liquid, such as sugar. It is measured using a refractometer and is expressed as a percentage. In the context of hydrocolloids, Brix measurement helps to understand the impact of sugar concentration on their properties and behavior.

What are hydrocolloid properties?

Hydrocolloid properties refer to the characteristics and functionalities of these substances. They include their ability to form gels, thicken liquids, stabilize emulsions, enhance texture, and improve mouthfeel in food products. Brix levels can affect these properties in hydrocolloids.

How does Brix influence hydrocolloid functionality?

Different Brix levels can impact hydrocolloid functionality in food applications. Higher Brix concentrations can enhance gel formation and thickening properties, while lower Brix levels may result in weaker gels or reduced thickening capabilities. It is important to consider Brix measurement when formulating hydrocolloid-based products.

What are the applications of hydrocolloids in the food industry?

Hydrocolloids find widespread applications in the food industry. They are used as stabilizers in dressings and sauces, thickeners in beverages and dairy products, emulsifiers in bakery items, and texture modifiers in processed meats. Brix measurement plays a role in optimizing hydrocolloid performance in these applications.

How does Brix affect hydrocolloid stability?

Brix levels can influence the stability and shelf life of hydrocolloid-based food products. Higher Brix concentrations can improve stability by enhancing gel or thickening properties, while lower Brix levels may result in reduced stability. Understanding the relationship between Brix and hydrocolloid stability is crucial in food formulation.

What are the challenges in Brix-controlled hydrocolloid formulations?

Formulating hydrocolloid-based food products with precise Brix control can be challenging. Achieving the desired hydrocolloid performance while maintaining consistent Brix levels requires careful formulation and process optimization. It is important to address these challenges to ensure product quality and consistency.

What are advanced techniques for Brix measurement in hydrocolloid systems?

Advanced techniques are available for measuring Brix in hydrocolloid systems. These include dynamic light scattering, nuclear magnetic resonance (NMR), and near-infrared (NIR) spectroscopy. These methods provide more detailed insights into the properties and behavior of hydrocolloids in relation to Brix concentration.

Can you provide case studies on Brix and hydrocolloids in real-world applications?

Yes, there are several case studies that demonstrate the influence of Brix on hydrocolloid properties in actual food industry applications. These case studies analyze specific examples of hydrocolloid-based products, highlighting the impact of Brix measurement on their performance and quality.

What are the future trends and research opportunities in Brix and hydrocolloids?

The field of Brix and hydrocolloids continues to evolve, with new trends and research opportunities emerging. Future studies may explore the development of innovative hydrocolloid formulations with controlled Brix levels, the impact of Brix on sensory attributes, and the influence of Brix on the nutritional aspects of products.

We recommend reading: How Hydrocolloids Improve Mouthfeel

About the Editor

About the Chef Edmund: Chef Edmund is the Founder of Cape Crystal Brands and EnvironMolds. He is the author of several non-fiction “How-to” books, past publisher of the ArtMolds Journal Magazine and six cookbooks available for download on this site. He lives and breathes his food blogs as both writer and editor. You can follow him on Twitter and Linkedin.

|

About the Author Ed is the founder of Cape Crystal Brands, editor of the Beginner’s Guide to Hydrocolloids, and a passionate advocate for making food science accessible to all. Discover premium ingredients, expert resources, and free formulation tools at capecrystalbrands.com/tools. — Ed |

Enjoyed this post? Subscribe to The Crystal Scoop

Food-science tips, ingredient know-how, and recipes. No spam—unsubscribe anytime.

- Choosing a selection results in a full page refresh.