Sodium Alginate

SUBSCRIBE TO OUR BLOG

Promotions, new products, and recipes.

Introduction

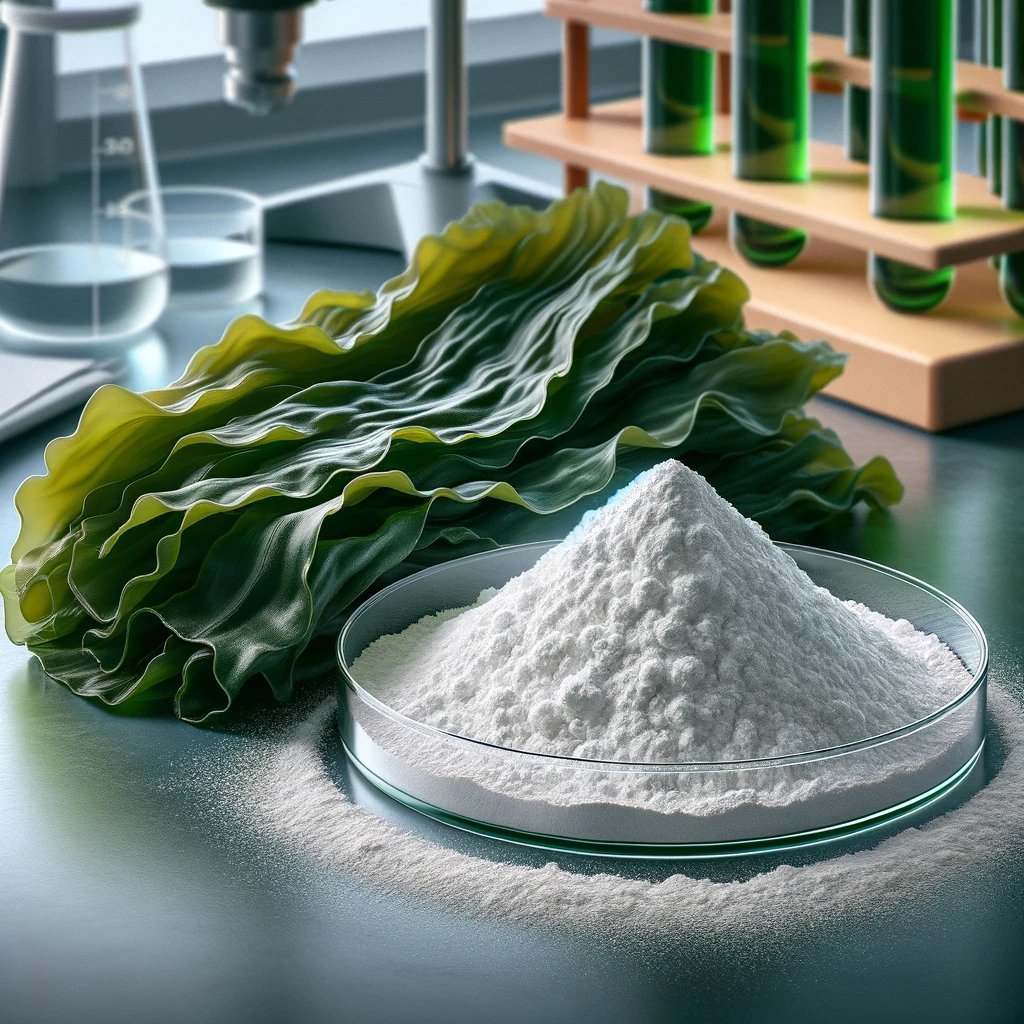

Sodium alginate, a multifaceted anionic polysaccharide derived from algae, plays a pivotal role across various industries due to its unique properties. In the realm of food, it's celebrated for its gelling and thickening prowess, essential for crafting textures and forms that delight the palate. Its interaction with calcium ions, through spherification, has revolutionized modern gastronomy, enabling chefs to produce spheres that burst with flavor. Beyond culinary arts, sodium alginate's applications extend to biomedical engineering, environmental science, and pharmaceuticals, where its capacity to absorb heavy metals, form hydrogels, and foster cell growth is highly valued. The adaptability of sodium alginate grades further enhances its utility, allowing for precision-tuned properties to meet diverse industry needs.

Key Takeaways

- Sodium alginate's gelling and thickening abilities make it a staple in food industry applications, particularly in modern gastronomy.

- The process of spherification, facilitated by sodium alginate, allows the creation of flavor-packed spheres, adding a visual and interactive element to dishes.

- Its versatility extends beyond the kitchen, with significant roles in biomedical engineering for tissue scaffolding and in environmental science for heavy metal absorption.

- The variability in sodium alginate grades enables customization of its properties, tailoring it to specific industry requirements.

- Sodium alginate's biocompatibility and biodegradability also make it suitable for pharmaceutical applications, highlighting its broad spectrum of utility.

Definition of Sodium Alginate

Sodium alginate is an anionic polysaccharide that is derived from algae. It is commonly used in various industries due to its unique properties and versatility. In the food industry, sodium alginate is used for its gelling and thickening properties, making it an essential ingredient for creating unique textures and forms. When combined with calcium ions, sodium alginate can undergo a process called spherification, which produces spheres or beads that burst with flavor when consumed. This technique has become popular in modern gastronomy, allowing chefs to create visually stunning and interactive dishes. Sodium alginate also finds applications in biomedical engineering, environmental sciences, and pharmaceuticals, thanks to its ability to absorb heavy metals, form hydrogels, and promote cell growth. The variability of sodium alginate grades allows for the fine-tuning of its properties, making it a valuable tool in various industries.

Overview of Applications

Overview of Applications of Sodium Alginate in Modern Gastronomy

Sodium alginate is a versatile ingredient commonly used in the food industry due to its unique properties as a thickener and gelling agent. With its wide range of applications, sodium alginate has become a valuable tool in modern gastronomy.

One popular application of sodium alginate is in spherification, a technique used to create spherical liquid-filled capsules that resemble caviar. By combining sodium alginate with a liquid ingredient and submerging it in a calcium chloride solution, it forms a gel-like membrane around the droplets, resulting in imitation foods like salmon roe or shark fin. This technique allows chefs to create visually appealing and texturally interesting dishes.

Sodium alginate is also known for its heat stability, making it suitable for applications that require gelling at high temperatures. This unique property makes it ideal for creating heat-stable gels, such as in reverse spherification. In this process, sodium alginate is mixed with a heat-stable ingredient, such as calcium carbonate, to form a gel that can withstand heat without losing its shape or texture.

Overall, sodium alginate has found a multitude of applications in the culinary world. Its ability to act as a thickener and gelling agent, along with its heat stability, makes it a valuable ingredient for chefs looking to create visually stunning and innovative dishes in modern gastronomy.

Properties of Sodium Alginate

Sodium alginate, a natural polymer derived from brown seaweed, possesses several unique properties that make it a valuable ingredient in modern gastronomy. One of its primary properties is its ability to form gels when combined with ions such as calcium. This gelling process occurs when the sodium alginate chains interact with divalent cations, resulting in the formation of crosslinks and the conversion of the liquid solution into a gel-like substance. The mechanical strength of the alginate gels can be adjusted by varying the concentration of sodium alginate and the divalent cations used.

Another important property of sodium alginate is its ability to form beads or capsules. When a sodium alginate solution is extruded into a solution containing calcium ions, it undergoes gelation, forming discrete droplets. These droplets can then be used to encapsulate various liquid ingredients or create unique textures in culinary presentations. The uniformity of the droplets can be achieved using different droplet production methods, including microfluidic droplet generation.

Sodium alginate is also known for its excellent biocompatibility and biodegradability, making it suitable for various biomedical and environmental applications. In bone tissue engineering, sodium alginate has been used to create scaffolds for promoting cell growth and regeneration. It has also been utilized in the efficient removal of heavy metals and the encapsulation of microbial cells for environmental remediation.

In conclusion, the unique properties of sodium alginate, including its gelling process, bead formation capability, and biocompatibility, make it an invaluable ingredient in modern gastronomy. Its versatility and wide range of applications in both food and non-food industries make it a sought-after ingredient for chefs, scientists, and engineers alike.

Physical Properties

Sodium alginate, a natural polymer derived from brown seaweed, possesses unique physical properties that contribute to its versatility in modern gastronomy. At the molecular level, sodium alginate is composed of repeating units of D-mannuronic acid and L-guluronic acid. These units can be arranged randomly or in blocks, giving rise to different physical characteristics.

Physically, sodium alginate usually appears as a white to pale yellow powder. It is soluble in water, forming a viscous solution. The solubility of sodium alginate can be affected by factors such as temperature, pH, and the presence of other substances. Its high viscosity and ability to gel make it a valuable ingredient for various culinary techniques, such as spherification.

The presence of D-mannuronic acid and L-guluronic acid units in sodium alginate influences its physical properties. The proportion and arrangement of these units can affect the gelation process, the mechanical strength of gels, and the overall texture of food products. For example, alginate gels with a higher proportion of guluronic acid units generally exhibit greater stiffness.

Mechanical Properties

Mechanical properties are an important aspect of sodium alginate, as they determine its performance in various applications. Sodium alginate exhibits unique mechanical characteristics that make it suitable for use in different industries.

The tensile strength of sodium alginate refers to its ability to withstand stretching or pulling forces without breaking. This property is influenced by the composition and arrangement of alginate chains. Sodium alginate typically has a moderate to high tensile strength, allowing it to withstand mechanical stress in applications such as tissue engineering and food industry.

Elongation at break, on the other hand, refers to the extent to which sodium alginate can stretch before it breaks. It is a measure of the material's flexibility and ability to undergo deformation without failure. Sodium alginate exhibits good elongation at break, making it suitable for use in processes such as spherification in modern gastronomy.

Young's modulus is a measure of the stiffness or rigidity of a material. Sodium alginate has a relatively low Young's modulus, indicating its flexibility and ability to deform under applied stress. This property is particularly advantageous in applications requiring materials to conform to specific shapes or contours, such as tissue engineering and food industry.

Overall, the mechanical properties of sodium alginate play a significant role in determining its suitability for various applications. Its moderate to high tensile strength, good elongation at break, and low Young's modulus make it a versatile material that can be utilized in fields like tissue engineering, where it can provide mechanical support to engineered tissues, and the food industry, where it can undergo deformation while maintaining structural integrity during processes like spherification in modern gastronomy.

Physicochemical Properties

Sodium alginate, a widely used ingredient in modern gastronomy, possesses unique physicochemical properties that make it suitable for various culinary applications. Its molecular structure is composed of repeating units of D-mannuronic acid and L-guluronic acid, with the possibility of other linkages.

One of sodium alginate's significant characteristics is its solubility in water. It can form a clear and viscous solution when dissolved in an aqueous medium, making it easy to work with in culinary processes. The viscosity of sodium alginate solutions can vary depending on factors such as the concentration and molecular weight of the alginate.

In addition to solubility and viscosity, sodium alginate also exhibits interesting interactions with divalent cations such as calcium ions. When sodium alginate comes into contact with divalent cations, it forms gel-like structures through a process called gelation. This property is particularly valuable in techniques like spherification, where sodium alginate solutions can be used to create spheres or encapsulate fillings.

Overall, the physicochemical properties of sodium alginate, including its molecular structure, solubility, viscosity, and interactions with divalent cations, make it a versatile ingredient in modern gastronomy. Its ability to form gels and its unique texture provide chefs with endless possibilities for creating innovative and visually appealing dishes.

Carbon Composites

Carbon composites are advanced materials that have gained significant attention in various applications due to their exceptional mechanical and physical properties. Researchers have been exploring different methods to enhance the performance of carbon composites, and one approach involves the utilization of sodium alginate.

Sodium alginate, an anionic polysaccharide derived from brown seaweed, has been combined with graphene oxide and biochar to create composite materials with enhanced properties for applications such as dye removal from wastewaters and adsorption of heavy metals. These composites exhibit improved adsorption capacities, making them effective in environmental remediation and purification processes.

Studies have focused on investigating the adsorption capacities and properties of sodium alginate-based carbon composites. Researchers have explored the effects of different parameters such as the concentration of sodium alginate, graphene oxide loading, and biochar content on the adsorption performance. It has been found that the incorporation of sodium alginate enhances the adsorption efficiency, while the addition of graphene oxide and biochar further improves the overall adsorption capacities and selectivity.

The synergistic combination of sodium alginate, graphene oxide, and biochar in carbon composites offers advantages such as high adsorption capacities, excellent stability, and easy synthesis. These composites have shown promising results in various environmental applications, including the efficient removal of dyes and heavy metals from contaminated water sources.

In conclusion, the incorporation of sodium alginate into carbon composites, along with graphene oxide and biochar, provides a versatile and effective solution for the adsorption of pollutants. The research in this field continues to expand, exploring different combinations and optimizing the adsorption capacities of these composite materials.

Gelling Processes and Formulations Involving Sodium Alginate

Sodium alginate is widely used in modern gastronomy for its unique gelling properties. One of the most popular applications of sodium alginate is in the technique of spherification, which involves creating gel-like spheres with a liquid core. This technique allows chefs to transform ordinary liquids into playful, visually striking spheres that burst with flavor when consumed.

In the process of spherification, sodium alginate is combined with a liquid ingredient and then dropped into a bath containing calcium chloride or another divalent cation. The alginate reacts with the calcium ions, forming a gel-like membrane around the liquid, while the inside remains liquid-filled. The resulting spheres maintain their shape until they are consumed, creating a delightful burst of flavor and texture.

In addition to spherification, sodium alginate is also utilized in various other gelling processes and formulations in the culinary world. It can be used to create gels, foams, and emulsions, adding texture and structure to dishes. The versatility of sodium alginate allows chefs to experiment with different forms and textures in their creations, opening up a world of possibilities in modern gastronomy.

Overall, sodium alginate offers chefs and food enthusiasts a wide range of options to elevate their dishes and create unique culinary experiences. Its gelling properties, especially in spherification, provide endless opportunities for creative presentations and flavor combinations. With sodium alginate, the boundaries of traditional cooking can be pushed, resulting in innovative and visually stunning dishes.

Gelling and Cross-Linking Mechanisms

Sodium alginate is a versatile ingredient used in modern gastronomy for its gelling properties. Its unique gelling and cross-linking mechanisms make it ideal for techniques like spherification. When sodium alginate comes into contact with divalent cations, such as calcium ions, a gel network is formed through a process called cross-linking.

The polymer chains in sodium alginate consist of alternating residues of guluronic acid and mannuronic acid. The guluronic acid residues play a crucial role in the gelling process. When calcium ions are introduced, they bind strongly with the guluronic acid residues, forming bridges between them. This cross-linking creates a three-dimensional gel network, trapping liquid within the gel structure.

The formation of calcium alginate beads is a result of this cross-linking process. When drops of sodium alginate solution are added to a bath of calcium chloride or another divalent cation, gelatinous spheres are formed. The calcium ions in the bath react with the guluronic acid residues in the sodium alginate, creating a gel-like membrane around each drop of liquid.

What makes this process particularly fascinating is the reversibility of the gelation. The gel network formed by the cross-linking of sodium alginate and divalent cations can break down when exposed to an excess of sodium ions. This means that the gel can transform back into a liquid state. This property allows for creativity and experimentation in modern gastronomy.

In summary, the gelling and cross-linking mechanisms of sodium alginate involve the binding of calcium ions to the guluronic acid residues in the polymer chains. This creates a gel network, enabling unique culinary techniques like spherification. The reversible gelation process adds to the versatility of sodium alginate in modern gastronomy.

Polyvinyl Alcohol in Gelation Processes

Polyvinyl Alcohol (PVA) is a commonly used substance in gelation processes involving sodium alginate. PVA plays a crucial role in these processes by serving as an encapsulating material for various applications in modern gastronomy.

One important application is the entrapment of microbial cells within PVA/sodium alginate (PVA/SA) beads. Microbial cells can be encapsulated within these beads to protect them during storage or to facilitate their controlled release in food products. PVA acts as a bonding agent with sodium alginate, creating a stable and biocompatible matrix for the entrapment of microbial cells.

The concentration of prepolymer and the reinforcing procedures used can greatly affect the micropores of PVA/SA beads. By varying the concentration of PVA and sodium alginate, the size and distribution of micropores can be controlled. This allows for the customization of the beads' properties, such as permeability and mechanical strength.

In gelation processes involving sodium alginate, the addition of PVA provides enhanced stability and mechanical properties to the resulting gel. The bonding mechanism between PVA and sodium alginate involves hydrogen bonding and electrostatic interactions. These interactions create a strong network structure, resulting in gels with improved mechanical strength and stability.

In conclusion, PVA plays a vital role in gelation processes involving sodium alginate in modern gastronomy. It enables the entrapment of microbial cells and provides enhanced stability and mechanical properties to the resulting gels. By adjusting the concentration of prepolymer and employing reinforcing procedures, the properties of PVA/SA beads can be tailored according to specific requirements.

Divalent Cations for Gelation of Sodium Alginate

Divalent cations play a crucial role in the gelation of sodium alginate, as they interact with the alginate chains to facilitate the gelling process. These cations, typically calcium, barium, or strontium, form cross-linking bridges with the carboxylic groups present in the alginate molecules.

The interaction between divalent cations and alginate chains occurs through ionic interactions, where the positively charged cations bind to the negatively charged carboxylic groups. This results in the formation of a gel network structure, giving the sodium alginate solution a gel-like consistency.

Calcium is the most commonly used divalent cation for gelation, as it forms strong and stable gels with sodium alginate. However, barium and strontium can also be utilized, albeit less frequently. Each divalent cation has its advantages and limitations. For instance, barium can provide gels with higher viscosity and strength compared to calcium, while strontium is known for producing gels with improved heat stability.

Divalent cations also play a vital role in the formation of calcium alginate beads, which find extensive use in encapsulation applications. In this process, sodium alginate is combined with a divalent cation solution, typically calcium chloride. The interaction between calcium ions and alginate chains results in the formation of calcium alginate beads, which can entrap various substances, such as flavors, colors, or even living cells.

Overall, the use of divalent cations for the gelation of sodium alginate offers great versatility in tailoring the properties of the resulting gels and enables the formation of calcium alginate beads with diverse applications in the food industry and beyond.

Reverse Spherification and Calcium Alginate Beads

Reverse spherification is a popular technique in modern gastronomy that utilizes sodium alginate to create unique and visually appealing culinary creations. By combining a flavored base liquid with calcium, it is possible to form calcium alginate beads, which encapsulate the liquid inside a thin gel membrane.

To begin the process, the desired flavored liquid is mixed with sodium alginate to form a solution. This solution is then dripped into a setting bath prepared with sodium alginate and sugar. The setting bath serves as a medium for the gelation of the sodium alginate solution.

Next, calcium is added to the flavored base liquid, and the mixture is carefully frozen in spherical molds. Freezing the liquid helps to retain its shape during the subsequent steps.

Once the spheres are frozen, they are carefully immersed in the setting bath for a specific amount of time. During this immersion, the calcium ions from the flavored liquid interact with the sodium alginate in the setting bath, resulting in the formation of a thin gel membrane around the liquid center. This process creates calcium alginate beads, which can be easily lifted from the setting bath and used as desired.

Reverse spherification with calcium alginate beads offers chefs and gastronomy enthusiasts the opportunity to present liquid-filled spheres in a visually stunning manner. The resulting culinary creations can provide bursts of flavor and texture when consumed, making it an exciting technique to explore in the realm of modern gastronomy.

Experiment with Sodium Alginate Yourself

Try an affordable packet of Cape Crystal Sodium Alginate below.

Double Network Hydrogels with Sodium Alginate

Double network hydrogels with sodium alginate have gained significant attention in the field of bioengineering research due to their potential applications in tissue regeneration and bone reconstruction. These hydrogels are composed of two distinct networks that work synergistically to provide enhanced mechanical properties and biocompatibility.

The first network is made up of sodium alginate, an anionic polysaccharide derived from brown seaweed. Sodium alginate is widely used in tissue engineering due to its unique properties, including biodegradability, biocompatibility, and the ability to form gels in the presence of divalent cations such as calcium ions. The alginate chains form a three-dimensional matrix that provides the structural integrity of the hydrogel.

The second network consists of a crosslinking agent, typically a covalent attachment of thiol groups to alginate. This network enhances the mechanical strength of the hydrogel, making it more suitable for load-bearing applications. Moreover, the covalent attachment of thiol groups to alginate promotes in situ gelling, allowing the hydrogel to conform to complex tissue defects or irregularly shaped bone defects.

Structural characterization studies have shown that double network hydrogels with sodium alginate exhibit desirable properties such as high water content, porosity, and tunable mechanical properties. These properties make them suitable for a range of biomedical applications, including bone tissue engineering, wound healing, and drug delivery systems.

In conclusion, double network hydrogels with sodium alginate have emerged as promising biomaterials in bioengineering research. Their unique combination of biocompatibility, bioactivity, and mechanical strength makes them a valuable tool in the development of advanced tissue regeneration and bone reconstruction strategies.

Food Industry Applications of Sodium Alginate

Sodium alginate, a key ingredient in modern gastronomy, is widely used in the food industry for its unique properties and versatility. One of its popular applications is in spherification, a technique that creates unique culinary experiences by transforming liquids into spheres with a thin gel-like membrane. In this process, sodium alginate is combined with a liquid, typically a flavorful juice or puree, and then dropped into a solution containing calcium ions. The crosslinking reaction between the calcium ions and the alginate forms a gel-like membrane around the liquid, creating small, flavorful balls that burst with flavor when consumed. The technique of spherification allows chefs to create visually stunning and interactive dishes, adding a touch of creativity and flair to their culinary creations. Sodium alginate's ability to form gels in the presence of divalent cations like calcium ions makes it an indispensable tool for chefs experimenting with textures and presentations. Its use in spherification has revolutionized modern gastronomy, offering endless possibilities for culinary innovation and sensory experiences.

Aqueous Solutions in the Food Industry

Aqueous solutions play a crucial role in the food industry due to their wide range of applications. These solutions, consisting of water as the solvent, are used as a medium to dissolve various substances and incorporate them into food products. One important ingredient commonly used in aqueous solutions is sodium alginate.

Sodium alginate is a natural polysaccharide derived from seaweed. It is known for its ability to thicken, gel, and stabilize aqueous solutions, making it a versatile ingredient in the food industry. When sodium alginate is added to a solution, it can increase its viscosity, giving it a thicker and more appealing texture. This makes it an ideal choice for use as a thickener in soups, sauces, and dressings.

Moreover, sodium alginate can also act as a gelling agent, allowing the aqueous solution to form a gel-like structure. This property is particularly beneficial in culinary techniques such as spherification, where sodium alginate is combined with other ingredients to create small, gelatinous spheres with different flavors and textures.

In addition to its thickening and gelling properties, sodium alginate also acts as a stabilizer in aqueous solutions. It helps to maintain the stability and uniformity of the solution, preventing ingredients from separating or settling.

Overall, sodium alginate is a valuable ingredient in the food industry due to its ability to enhance the texture, improve stability, and create unique culinary experiences. Whether it is used as a thickener, gelling agent, or stabilizer, sodium alginate contributes to the success of various food applications in aqueous solutions.

Medical Applications of Sodium Alginate

Sodium alginate has also found a wide range of applications in the medical field. It is used as a hemostatic agent, which helps to stop bleeding during surgical procedures by forming a gel-like film over the wound. This film acts as a barrier against further blood loss and reduces the risk of postoperative complications. Its ability to form a gel-like structure also makes it useful in wound dressings, as the gel can help to keep the wound area moist and protect it from infection. Furthermore, sodium alginate has been used in drug delivery systems, where its gelling properties can help to control the release of active ingredients for sustained therapeutic effects.

cean-based food products, and it has a number of other useful applications. It is a safe and convenient material with many beneficial properties, and its widespread use looks set to continue.In conclusion, sodium alginate is an essential ingredient in many food and cosmetic products, and its versatile properties are being harnessed in an ever-increasing range of applications. Its use is increasing due to its safety and convenience, as well as its ability to improve the quality of many products. With the right research and development, it has the potential to revolutionize various industries in the near future.

Sodium alginate is a naturally occurring polymer derived from seaweed. It is a white to yellow-brown powder that has excellent emulsifying, gelling, and stabilizing properties. It is the most widely used form of alginate due to its high solubility in water and its wide range of applications. Sodium alginate can be used as an additive in food. It can be used as a thickener, stabilizer, texturizer, and suspension agent. Its ability to form gels with calcium ions makes it an ideal ingredient for making ice creams, custards, puddings, and jellies. In the textile industry, sodium alginate is used in printing processes to create a resistive barrier on fabric that prevents dyes from spreading.

make a soft gel, sodium alginate is used in combination with other ingredients, such as calcium chloride. The combination of the two substances produces a strong gel that can be used to create unique textures and shapes in food dishes. It also has applications in food manufacturing and pharmaceuticals where it is used to form capsules that can quickly dissolve in liquids. Sodium alginate is an important ingredient in the oceanography field where its used to study the movement of ocean currents. It can also be used in dyes, fabric printing, and paper manufacturing.

Conclusion

Sodium alginate is an important idustry ingredient. It is a gum-like substance derived from brown seaweed and other marine algae. It is used in food processing as a thickener, stabilizer, and emulsifier, and it can also be found in various health care products. In addition to its use in the food industry, sodium alginate has many applications.

Sodium alginate has been used to make edible films and coatings for food, as well as to stabilize foams and emulsions. It is also used in the pharmaceutical industry as an excipient and in dentistry for making impressions of teeth.

Sodium alginate is a polysaccharide composed of two sugar units: mannuronic acid (M) and guluronic acid (G).

Sodium alginate also finds use in the textile printing industry as a thickener for reactive dyes. It can also be used in combination with other thickeners for screen printing to create a smooth fabric finish. Additionally, sodium alginate can be used in the production of artificial fibers, and as an emulsifying agent in cosmetics and other personal care products.

Sodium alginate's versatility makes it a vital ingredient for many industries, from food to cosmetics. For example, when combined with calcium chloride, sodium alginate forms a gel which can be used in medical applications such as wound dressings and tissue engineering. It is also used in the production of paper products such as wallpaper, and for oil spill containment booms.

Sodium alginate is also widely used in the printing and food industries due to its ability to bind dyes, pigments, and other materials. It can be used to make edible inks for food printing, as well as a coating on paper products such as labels, packaging, and wallpaper. Additionally, sodium alginate has been found to be an effective oil-spill dispersant and is used in oil spill clean-up operations.

Sodium alginate is also a common component in food processing, as it helps to emulsify and preserve food products. It can be found in many dairy products such as ice cream and cheese, as well as other processed foods like dressings and sauces. In addition, sodium alginate has been used to create edible films which can help keep food fresh for longer periods of time .

In conclusion, sodium alginate stands out as an invaluable ingredient, bridging the gap between culinary innovation and scientific advancement. Its gelling properties have not only transformed the way we experience food but also contributed to progress in medical and environmental technologies. The ability to fine-tune its characteristics ensures that sodium alginate will continue to be a key player in various fields, pushing the boundaries of what is possible in both the kitchen and the laboratory.

Frequently Asked Questions

-

What is sodium alginate? Sodium alginate is a natural polysaccharide extracted from brown seaweed, used for its gelling, thickening, and stabilizing properties.

-

How is sodium alginate used in modern gastronomy? It is used in spherification to create caviar-like spheres, as a thickener for sauces and dressings, and as a stabilizer to maintain the consistency of food products.

-

Can sodium alginate be used in high-temperature cooking? Yes, sodium alginate is heat-stable, making it suitable for high-temperature culinary applications without losing its gelling properties.

-

Are there any non-food applications of sodium alginate? Yes, it is used in biomedical engineering for tissue scaffolds, in environmental science for absorbing heavy metals, and in pharmaceuticals for drug delivery systems.

-

Is sodium alginate safe to consume? Sodium alginate is generally recognized as safe (GRAS) by the FDA and is widely used in the food industry within regulated limits.

Well That's the Story. I hope it was helpful. Let's Hear Your Thoughts!

We've shared our insights, and now it's your turn! Have an opinion, a question, or a story to share about this article? Dive into the comments below and join the conversation. Your voice is a crucial part of this community, and we're eager to hear what you have to say.

We would appreciate hearing from you. Please add your comments below. We will reply to them.

See: The Hydrocolloid Glossary

You might enjoy these other article about alginates:

Elevate Your Culinary Creations! 🍽️✨

Every dish deserves the perfect texture to complement its flavors. Why settle for anything less than perfection? With Cape Crystal Brands Food Texture products, you don't have to. Whether you're crafting velvety sauces, glistening gels, or fluffy mousses, our range ensures you get the consistency you desire every single time.

Don't just cook—create masterpieces. Dive into the world of culinary textures and elevate every meal. Shop now and experience the magic of Cape Crystal!

🛍️ Click Here to Explore Cape Crystal Brands Food Texture Products!

About the Editor

About the Chef Edmund: Chef Edmund is the Founder of Cape Crystal Brands and EnvironMolds. He is the author of several non-fiction “How-to” books, past publisher of the ArtMolds Journal Magazine and six cookbooks available for download on this site. He lives and breathes his food blogs as both writer and editor. You can follow him on Twitter and Linkedin.

- Choosing a selection results in a full page refresh.